Press Releases and Recent Postings

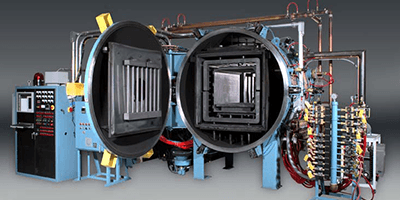

- High Temp High-Vacuum Brazing Furnaces for Precision Heat Treating September 1, 2021

- Multiple Metal Injection Molding and 3D Printing/Additive Furnaces August 17, 2021

- New High Temp High-Vacuum Brazing Furnaces August 17, 2021

- Case Study for Workhorse Precision Brazing Furnace May 1, 2020

- Case Study for Sintervac High Temperature Vaccuum Furnace April 27, 2020

- Case Study: Vacuum Furnaces in the Aerospace Industry February 11, 2020

- New 3,200ºc Furnace From Centorr Vacuum Industries November 22, 2019

- Centorr Vacuum Industries Has Three (3) New LF Series Laboratory Furnaces For Sale November 5, 2019

Contact Us

800.962.8631

603.595.7233