All Furnace Photos

Furnace Photo Galleries

View Images of the Furnaces That Centorr Vacuum Industries Manufactures

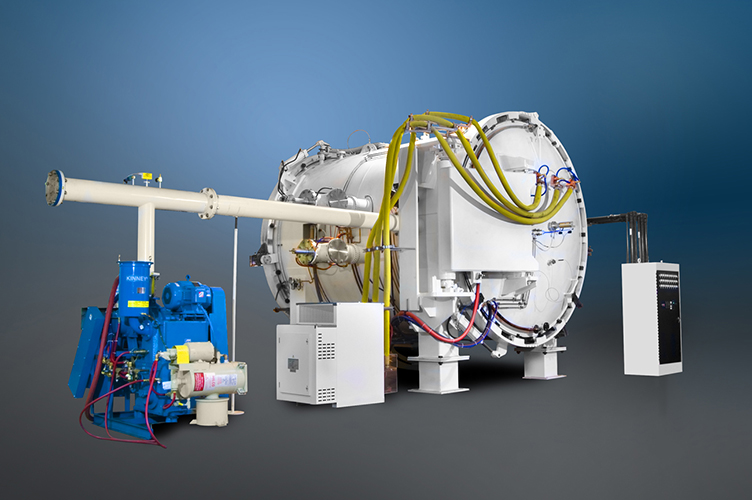

Production Vacuum Furnaces

Production Vacuum Furnaces

Standard designs augmented by specialized, custom-designed vacuum furnaces for processing a variety of metals, ceramics, composites, and carbon/graphite materials.

Sintervac™ Furnaces

Sintervac™ Furnaces

Designed for both development and quality assurance tasks, a typical furnace cycle takes less than 12-18 hours. Two temperature ranges are available: one for steels and tungsten carbide and the other for non-oxide ceramics. Optional equipment can be debinding and positive pressure operation.

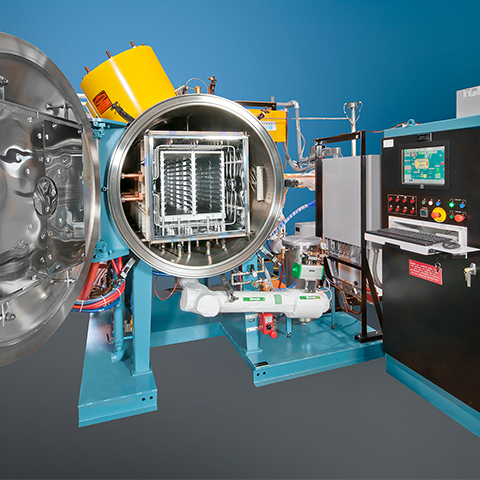

Workhorse® Furnaces

Workhorse® Furnaces

A vacuum/controlled atmosphere batch furnace where the basic design is comprised of three standard hot zone sizes in four different temperature ranges, with a long list of optional equipment that makes this one of the most versatile custom-designed furnaces available today.

MIM Vac Vacuum/Controlled Atmosphere

MIM Vac Vacuum/Controlled Atmosphere

Purpose built for the debinding and sintering of additive manufactured and 3D printed parts, as well as those produced by the metal injection molding process. The MIM-Vac M™ is Centorr/Vacuum Industries' latest offering in its line of custom-engineered high temperature vacuum/controlled atmosphere furnaces.

Vacuum Hot Press Furnaces

Vacuum Hot Press Furnaces

Centorr/Vacuum Industries’ Hot Press Sintering Furnaces are part of a long standing tradition of quality, dependability, and innovation in high temperature vacuum and controlled atmosphere heating technology.

Laboratory & Research Furnaces

Laboratory & Research Furnaces

Centorr Vacuum Industries manufactures a diverse line of laboratory vacuum and controlled atmosphere furnace equipment that is suitable to most customer’s needs. We start with a thorough understanding of your processes and furnacing requirements, and then help you select a system that best fits your requirements. (Custom furnaces also available.)

CVD and CVI Vacuum and Controlled Atmosphere Furnaces

CVD and CVI Vacuum and Controlled Atmosphere Furnaces

Centorr/Vacuum Industries high temperature, low pressure CVD furnaces provide stable, repeatable conditions for production of high performance materials from vapor phase feedstocks involving reaction temperatures up to 2200°C.

Continuous Furnaces

Continuous Furnaces

Centorr/Vacuum Industries graphite pusher furnace designs incorporate variable speed pusher, optional atmosphere debinding furnaces, high temperature sintering furnace, cooling tunnel, load locks, and work box unloading system; while the line of continuous belt furnaces are available in either metal or graphite hot zones rated to temperatures up to 2000°C

Custom and Kit Furnaces

Custom and Kit Furnaces

Centorr Vacuum Industries manufactures a line of custom-built vacuum and controlled atmosphere furnace equipment that can be customized to a customer’s individual needs.

Contact Us

800.962.8631

603.595.7233