Photo Gallery

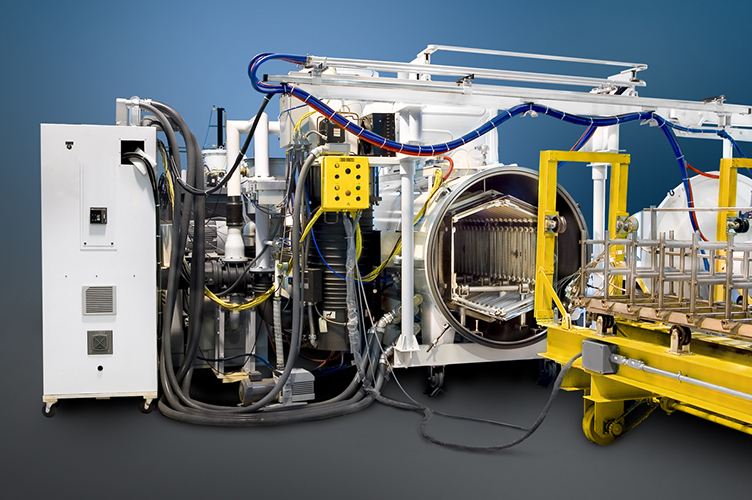

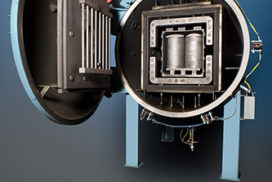

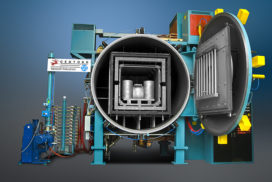

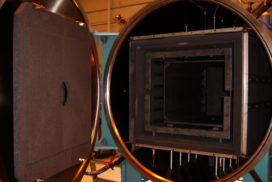

Sintervac Furnaces

Designed for both development and quality assurance tasks, a typical furnace cycle takes less than 12-18 hours.

Designed for both development and quality assurance tasks, a typical furnace cycle takes less than four hours. Two temperature ranges are available: range A, 1600°C max. for steels and tungsten carbide and range C, 2200°C max. for non-oxide ceramics. Optional equipment can be selected for automatic temperature control, remote programming, repeated delube cycles, and control of various process parameters.

Contact Us

800.962.8631

603.595.7233