All Series

Laboratory Vacuum Furnaces

High Temperature Vacuum Furnaces and Controlled Atmosphere Furnaces for Laboratory and Research and Development

Centorr Vacuum Industries manufactures a diverse line of laboratory vacuum and controlled atmosphere furnace equipment.

Laboratory vacuum furnaces are specialized heating furnaces used for processing materials under controlled temperature and vacuum conditions. These furnaces create a low-pressure environment, by removing air and other gases from the chamber, allowing for specific heat treatments, material synthesis, and other processes. The furnaces can also be operated in partial or positive pressure of Ar, N2, or Hydrogen gases.

Our laboratory vacuum furnaces, and R&D vacuum furnaces are suitable for most lab and research customer needs. Laboratories and research facilities use CVI vacuum furnaces for experimentation and development of new materials and processes amongst other uses. For example, researchers can study the effects of temperature and vacuum conditions on different metals and ceramics materials.

View CVI Graphitization Furnaces

Laboratory vacuum furnaces achieve exceptional temperature control, high vacuum environments and uniform heating.

These furnaces can achieve high temperatures, often exceeding 1000 degrees to 3000 degrees Celsius, depending on the model and design. Precise temperature control is a crucial feature for various applications, such as heat treatment, annealing, and material testing. The vacuum environment prevents oxidation and contamination of the materials being processed. It is particularly important for heat treatment processes, where maintaining a controlled atmosphere is critical. CVI’s laboratory vacuum furnaces are designed to provide uniform heating throughout the chamber to ensure consistent results across the processed materials.

A leader in vacuum furnace design and manufacturing, we start with a thorough understanding of your processes and laboratory furnacing requirements. We then help you select an available laboratory vacuum furnace system that best fits your lab and R&D requirements or, we customized a laboratory vacuum furnaces for your specific requirements.

Several laboratory vacuum furnace applications include:

- Annealing

- Carbon Fiber Processing

- Ceramic Firing

- Heat Treating

- Homogenization

- Melting

- Sintering

- Wetting Studies

- Thermocouple Calibration

- Drawing of Optical Fibers

- Brazing

- Powder Metallurgy

- Pressure Sintering

- Heat Treating

- Crystal Growth

- Melting

- Ceramic Firing

- Degassing

With over 80 years of combined vacuum furnace-building experience, we are uniquely suited to offer the perfect laboratory furnace equipment for your individual processes, unique lab vacuum furnace sizes, and control requirements.

Please see the furnace links below to view the variety of laboratory vacuum furnaces and features available:

Laboratory Vacuum Furnace Selection

Click on series number to view product page.| Product Series | Furnace or Equipment Type | Applications/Processes | Max Temp. |

|---|---|---|---|

| 2 | Oxygen Monitors and Inert Gas Purifiers | Argon & Helium Purifier, Oxygen Purifier, Nitrogen Purifier | N/A |

| 5 | Bell Jar Furnaces | Powder Melting, Arc Casting, Metallic & Non-Metallic Buttons, Annealing, Compound Synthesis, Material Densification | Over 3500°C (6332°F) |

| 5SA | Single Arc Furnaces | Powder Melting, Arc Casting, Metallic & Non-Metallic Buttons, Annealing, Compound Synthesis, Material Densification, Crucible Cover Welding, Thermocouple Junction Welding | Over 3500°C (6332°F) |

| 5TA | Tri-Arc Furnaces | Czochralski Crystal Growth, Melting Point Determination, Freeze Purification, Arc Casting, "Splat" Cooling, Powder Melting, Annealing, Crucible Welding, Compound Synthesis, Thermocouple Junction Welding | Over 3500°C (6332°F) |

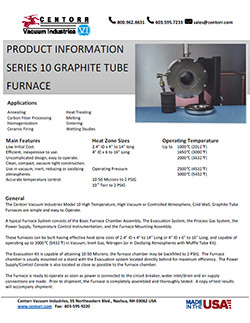

| 10 | Graphite Tube Furnace | Annealing, Carbon Fiber Processing, Ceramic Firing, Heat Treating, Homogenization, Melting, Sintering, Wetting Studies | Up to 2750°C (4982°F) |

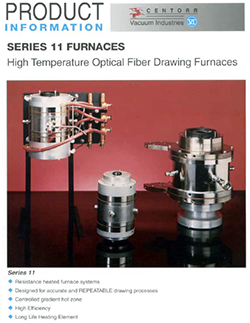

| 11 | High Temperature Optical Fiber Drawing Furnaces | Drawing of Optical Fibers | 2300°C (4172°F) |

| 15 | Top Loading Vacuum Furnace | Brazing, Heat Treating, Crystal Growth, Melting, Ceramic Firing, Sintering, Degassing, Thermocouple Calibration. | 2500°C (4532°F) |

| 16 | Top Loading Vacuum Furnace | Brazing, Heat Treating, Crystal Growth, Melting, Ceramic Firing, Sintering, Degassing, Thermocouple Calibration. | 3000°C (5432°F) |

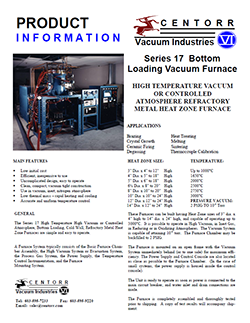

| 17 | Bottom Loading Vacuum Furnace | Brazing, Heat Treating, Crystal Growth, Melting, Ceramic Firing, Sintering, Degassing, Thermocouple Calibration. | 3000°C (5432°F) |

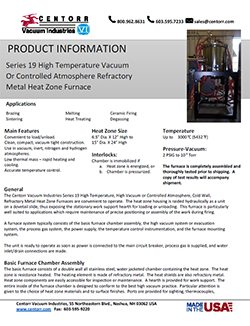

| 19 | Bottom Loading Metal Bell Jar Furnace | Brazing, Melting, Sintering, Heat Treating, Ceramic Firing, Degassing. | 3000°C (5432°F) |

| 45 | Top Loading Graphite | Annealing, Brazing, Crystal Growth, Ceramic Firing, Degassing, Heat Treating, Melting, Sintering. | 3000°C (5432°F) |

| 46 | Bottom Loading Graphite | Annealing, Brazing, Crystal Growth, Ceramic Firing, Degassing, Heat Treating, Melting, Sintering. | 2800°C (5072°F) |

| 50 | Front Loading | Annealing, Brazing, Casting, Ceramic Firing, Degassing, Diffusion Bonding, Heat Treating, Homogenization, Melting, Sintering. | 2800°C (5072°F) |

| 60 | Front Access | Research and Development | 3000°C (5432°F) |

| 2100/2110 | System VII/Super VII | Multipurpose Vacuum Metallurgical Systems | Up to 3000°C (5432°F) |

| HP | Vacuum Hot Press Furnace | Hot compacting of carbide, oxide, and nitride mixtures. Development of ceramic composite materials, diffusion bonding, metal matrix bonding, development of superconductors | up to 3000°C (5432°F) |

| LF Graphite Hot Zone | Top Loading Furnace | Multi-purpose | up to 3000°C (5432°F) |

| LF Refractory Metal Hot Zone | Top Loading Furnace | Multi-purpose | up to 2000°C (3632°F) |

| Testorr™ | Materials Testing Furnace | Air, Ar, N2, He, H2, O2 | Up to 2500°C (4532°F) |

| WA | Wire Anneal Furnace | Wire Annealing (Replaces Vacuum Batch Furnaces) | Up to 1600°C (2912°F) |

Contact Us

800.962.8631

603.595.7233