TT SERIES Materials Testing Testorr™

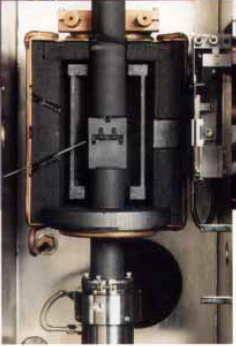

The Centorr Vacuum Industries Testorr™ Furnace System provides a variety of tightly controlled, elevated-temperature environments for materials testing within the confines of a standard testing frame.

A choice of the five interchangeable hot zones, each with its own thermal and atmosphere capabilities, are available for use with the standard vacuum chamber. Collectively, the heating systems provide for uniform specimen temperature of 300°C to 2300°C in a wide range of atmospheres. In the high-temperature region (1200° to 2300°C), a temperature uniformity of better than ±5°C is typical.

In addition to providing temperatures up to 2500°C, the Testorr Furnace System has been designed to interface with optical and contact extensometers, hydraulic grips, internal load cells and fixtures (3- and 4-point bend, compression, etc.) used for high temperature materials testing. Appropriately sized ports are provided for water cooling, hydraulic and electrical connections to each of the devices listed above.

Features

- Five interchangeable, resistance-heated hot zones

- Temperatures of 300°C to 2500°C

- Pressure range of 10-6 torr to 2 PSIG

- Tensile testing hot zone has a 3.25" grip-to-grip distance

- Hot zones are designed for use in Argon, Helium, Hydrogen, Nitrogen, Oxygen, or vacuum atmospheres

- Chamber is designed for use with optical and contact extensometry

- Temperature control accuracy of ±0.01% full scale

- Chamber is designed to accommodate various testing requirements

Specifications

| Hot Zone Model |

Maximum Element Temp. |

Heating Element |

Temperature Uniformity |

Atmosphere Compatibility* |

Vacuum Compatibility** |

|---|---|---|---|---|---|

| 2 x 2-G-G-20 2 x 2-G-G-25 |

2000°C 2500°C |

Graphite 2" (51mm) D 2" (51mm) H |

±5°C .5" (13 mm) gauge length | Ar, N2, He | RT-1800°C to 1x10-6 Torr above 1800°C**** |

| 4 x 8-G-G-20 4 x 8-G-G-25 |

2000°C 2500°C |

Graphite 4" (102mm) D 8" (203mm) H |

±10°C within 3.5" (89 mm) D 6" (152mm) H |

Ar, N2, He | RT-1800°C to 1x10-6 Torr above 1800°C**** |

| 4 x 8-W-D-20 4 x 8-W-A-25 |

2000°C 2500°C |

Tungsten Mesh 4" (102mm) D 8" (203mm) H |

±10°C within 3.5" (89 mm) D 6" (152mm) H |

Ar, N2, He, H2*** | RT-2000°C to 1x10-6 Torr 2000-2500°C**** |

| 6 x 8-W-D-20 6 x 8-W-A-25 |

2000°C 2500°C |

Tungsten Mesh 6" (152mm) D 8" (203mm) H |

±10°C within 5" (127 mm) D 6" (152mm) H |

Ar, N2, He, H2*** | RT-2000°C to 1x10-6 Torr 2000-2500°C**** |

| 3 x 8-K-I-11 | 1100°C | Kanthal 3" (76mm) D 8" (203mm) H |

±10°C within 2.5" (64 mm) D 6" (152mm) H |

Air, Ar, N2, O2*** | RT-1100°C to 1x10-6 Torr |

*Custom designed systems are available for corrosive gases.

**Operation from 10-2 torr to 10-6 torr requires selection of Model 06A6 diffusion pumping, turbo-molecular or cryogenic pumping systems.

***Flammable gas safety systems are added to the Testorr furnace if the option is exercised.

****Consult vapor pressure chart.

Contact Us

800.962.8631

603.595.7233