5SA SERIES

Single Arc Furnace

Compact, easy to operate, lightweight and inexpensive basic research tool used to produce high purity melts.

5SA SERIES Single Arc Furnace

The Model 5SA Single Arc Furnace is a compact, easy to operate, lightweight and inexpensive basic research tool used to produce high purity melts. The furnace system consists of the Single Arc Furnace, a D.C. power supply, and a set of water-cooled power cables to bring power and water to the furnace. Because of its simplicity, ease of access into the furnace, and small volume, the furnace is very easily purged. Work specimens are, therefore, very quickly prepared and a very high degree of purity is maintained from sample to sample.

Due to the extremely high temperatures available by the arc technique, temperature in excess of 3500°C can be attained. Material such as molybdenum and tungsten are readily melted and extremely high purity is attained. More difficult materials such as zirconium oxide, aluminum oxide, etc., are melted by surrounding the material by the arc plasma.

In the past, arc melting furnaces tended to be large, cumbersome and expensive; but, there is a unit that can be carried under your arm, set-up in minutes on any convenient table top, and is such a marvel of simplicity that anyone can operate it.

Features

- Ease of Operation

- Compact and Portable

- Extremely dependable and versatile

- Low initial cost

- Instant high temperature

- Accepts variety of hearth configurations

- Extremely pure melts

- Provision for titanium getter

Specs

| Maximum Temp: | Greater than 3500°C (6332°F) |

| Time to Temperature: | Instantaneous |

| Usable Hearth Diameter: | 1 5/8" aid. |

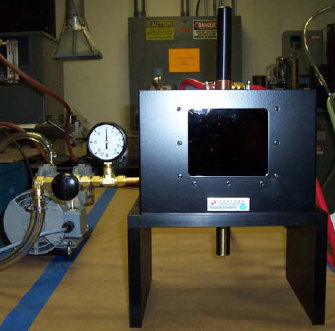

| Furnace Size: | 8" deep x 12" wide x 17" high |

| Utility Requirements: | Electrical - 300 Amps, D.C. Water - 1 GPM @ 70°F and 50 PSI Inert Gas - 1 to 5 CFH - Argon or Helium |

| Equipment: | Single Arc Furnace Water-cooled Power Cables 300 Amp D.C. Power Supply Load-Lock (optional) |

| Spares: | Replaceable Electrodes Extra Hearths |

Applications & General Info

Applications

- Powder Melting

- Arc Casting

- Metallic and Non-Metallic Buttons

- Annealing

- Compound Synthesis

- Material Densification

- Crucible Cover Welding

- Thermocouple Junction Welding

General Information

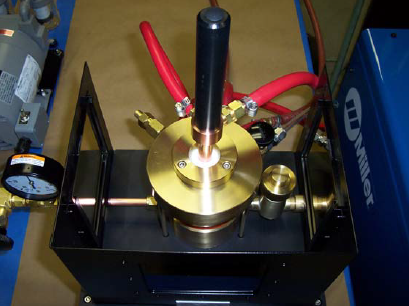

The Model 5SA single Arc Furnace consists of upper and lower water-cooled sections separated by a Pyrex observation tube. The observation tube serves as an insulator between the upper (negative) section, and the lower (positive) section. Power and water are fed to 4each of these sections by water-cooled power cables. Penetrating the top section is a copper stinger rod which carries the tungsten electrode. This rod is mounted into a swivel ball which allows it to have angular as well as vertical movement. Because power is brought to the electrode by precision fits between the rod and the ball and the ball and the upper water-cooled section, there are no heavy cables or hoses attached to the handle of the stinger. The bottom section contains a tapered opening which accepts a variety of copper hearths. These hearths are secured in position by means of quick-acting clamps.

Provision is made in this furnace for attaching to a mechanical pump for evacuation prior to backfilling if this is desired. Ports are also provided for inert gas inlet and outlet. A recent innovation is the addition of a load-lock which can be attached to the base of the furnace and permits addition of material to the melt while in operation. The complete assembly is bolted together and mounted on a small base which makes setting-up simply a matter of clearing space on your work bench.

To use this furnace, the work is placed in the cup of the hearth. The hearth is inserted into the tapered hole in the bottom of the furnace and clamped into position. The furnace is then purged either by use of a mechanical pump, followed by backfilling with inert gas such as argon or helium, or the unit is simply purged by a flow of inert gas. Once the system has been purged, the desired power setting on the power supply is set and the electrode is then brought to a position above the material to be melted and an arc is struck. It is advisable to move the singer around the top of the specimen in order to melt uniformly and homogeneously. On occasion, the specimen is turned over and re-melted. A small, separate cup is provided in the base of the furnace for melting a small piece of titanium prior to melting the specimen, to remove any possible impurity from the furnace cavity.

In order to operate this furnace, it is necessary that it be connected to a 30 volt, 300 Amp, direct current, electric welding type power supply.

This furnace is available with or without power supply and/or water-cooled power cables.

Contact Us

800.962.8631

603.595.7233