WORKHORSE PRECISION BRAZING FURNACE FOR COPPER BRAZING.

Nashua, NH, 30 April 2020-

Centorr Vacuum Industries worked closely with a customer in the industrial products industry on an application involving the use of copper brazing to join pieces of stainless steel materials.

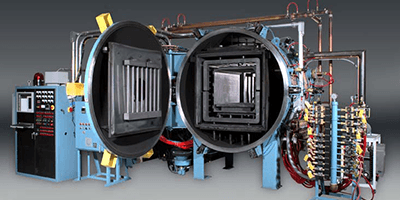

Due to the delicate balance between vaporization and safe processing of copper braze materials in vacuum, the customer placed an order for a Centorr Vacuum Industries Workhorse™ furnace with its proprietary G-10504B partial pressure control system

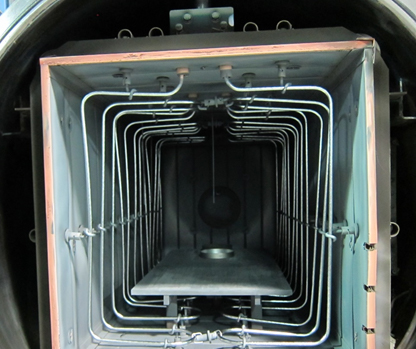

Previous processing of the material in high vacuum resulted in the Copper braze material vaporizing and condensing inside the vacuum furnace hot zone at all the cold surfaces (such as the powerfeedthrough locations and the front and rear hot zone doors. This is evidenced in the photos below showing extensive copper plating in the ‘cold’ areas.

To minimize this process offgassing, Centorr provided its partial pressure control system consisting of a small micrometer needle valve and on/off roughing valve. During operation the high-vacuum pumping system is valved off and the partial pressure gas control system allows for a fine degree of clean, non-reactive Argon gas to bleed into the chamber spoiling the vacuum level to a controllable range between 1 and 1000 microns (ie – 10-3 to 1 torr). This vacuum level is above the threshold where the Copper materials will vaporize at the brazing temperatures used.

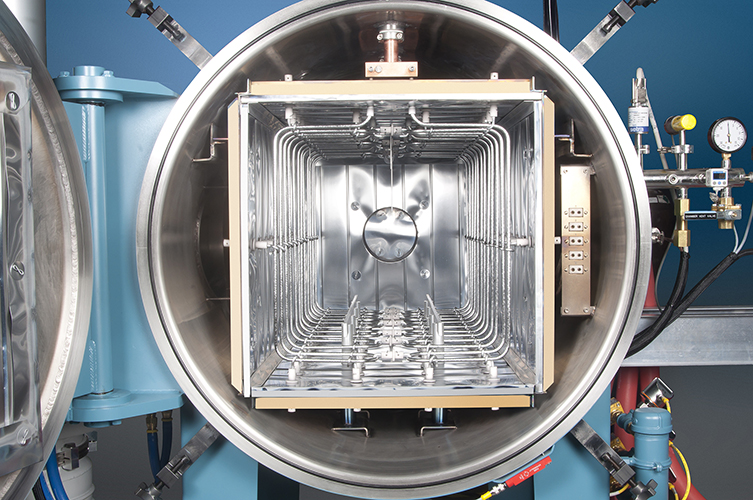

For cases where the customer must process the copper braze materials in high-vacuum (due to part configuration and need for vacuum environment in the sealed brazed parts), Centorr has designed its vacuum furnace hot zones to withstand a high-degree of braze material condensation.

CVI’s rod, overbend elements in a square hot zone cross-section result in fewer powerfeedthrough connections when compared to cylindrical round hot zones with flat ribbon elements - over 4 times less element connections! The hot zone ends are also constructed with C-channel coverings on all the exposed edges which minimizes the amount of braze condensate that can infiltrate into the refractory metal shield pack causing hot zone weight gain and poor insulation properties between the various layers of shielding. For these reasons, the Workhorse™ line of vacuum furnaces have proven themselves in applications for precision brazing of copper materials

Centorr Vacuum Industries is a high temperature vacuum / controlled atmosphere furnace manufacturer with an installed base of over 6500 units worldwide. Their furnace offering ranges from large commercial and production units with hot zones over 3m x 3m x 3m, to smaller Lab and Research & Development furnaces for use at temperatures up to 3500°C. They are located in Nashua, NH with a fully staffed Aftermarket Field Service group, and Applied Technology Center offering R&D support and toll production service. For more information please contact the sales department at 603-595-7233 or visit their website: www.centorr.com