All Series

Sintering Furnaces for Metals and Ceramics

Centorr Vacuum Industries has a rich history and foundation in creating furnaces for the sintering of several different metals and ceramics materials at temperatures ranging from 1000°C up to 2450°C.

Request Quote

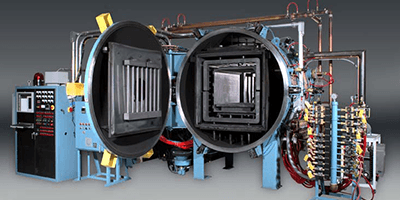

Centorr sintering furnaces offer a variety of furnace designs and configurations.

Sintering furnaces are used in a variety of industries for the purpose of sintering. Sintering is heating a material to a specific temperature below its melting point but high enough to cause its particles to adhere to each other. There are three main stages of sintering, heating, cooling and holding. Sintering is commonly used in powder metallurgy, ceramics manufacturing, and various other fields.

These designs include small laboratory units as well as full size production units [and these furnaces are available in a variety of configurations including top-loading, bottom-loading or front-loading designs.

Sintering Furnaces are Used in a Variety of Industries

Centorr Vacuum Industries provides sintering furnaces that are used in many varied industries that have robust manufacturing requirements with delicate process control needs. Typical industries that use sintering furnaces include:

- Cutting Tool Manufacturers

- Powdered Metal Parts Users

- Advanced Ceramics Companies

- Body and Vehicle Armor Producers

- Aerospace Companies

Available Sintering Furnaces

For more information on Centorr Vacuum Industries' line of Sintering furnaces, please click on the links below to view the many sintering furnace models available for your needs:

Laboratory Sintering Furnaces:

Production Sintering Furnaces:

-

- Series 3530 Vacuum Controlled Atmosphere Batch Furnace

- Series 3570 High Temperature Vacuum / Controlled Atmosphere Furnace

- Series 3710 Sintervac™ Sintering Furnaces

- Series 3800 High Temperature, Low Pressure CVD Furnaces

Continuous Sintering Furnaces:

-

- Series BF Belt Furnace - Controlled atmosphere continuous furnace.

- Series PF Pusher Furnace - Controlled atmosphere continuous furnace.

- Series 3610 Rotary Table - High temperature annealing of wire in protective atmosphere.

Sintering Furnace Applications

Common applications are the sintering of metal or ceramic powders, carbon/graphite/CFC processing, the manufacturing of hard metals such as Tungsten and Carbide, and most non-oxide advanced ceramics including BN, AlN, SiC (pressureless sintering, reaction-bonded, and recrystallized), Si3N4, B4C, AlON, and others. These materials can be processed in any combination of furnace atmospheres including high-vacuum, rough vacuum, partial pressure, or positive pressures of inert or Hydrogen gases. Key applications of sintering furnaces include:

Powder Metallurgy: Sintering furnaces are extensively used in the powder metallurgy industry to produce metallic components. Metal powders are compacted into a desired shape using pressure, and then sintered in a furnace to bond the particles together and create a solid object. This process is widely used in automotive, aerospace, and manufacturing industries to produce parts such as gears, bearings, and cutting tools.

Ceramics Manufacturing: Sintering is a crucial step in the production of ceramic materials. Ceramic powders may be pressed into a specific shape and then sintered in a furnace to create dense, solid ceramic components. This sintering process is used in the manufacturing of tiles, bricks, electronic ceramics, and various industrial components.

Electronics: Sintering furnaces are used in the electronics industry for the production of electronic components such as capacitors, resistors, and semiconductor devices. Sintering is employed to bond metal or ceramic particles together and to create dense, reliable connections between components.

Advanced Materials: Sintering is used in the production of advanced materials such as composites, metal matrix composites, and ceramics matrix composites. These materials often require specific temperature profiles and controlled atmospheres during the sintering process to achieve desired properties such as strength, hardness, and thermal conductivity.

Medical Devices: Sintering furnaces are used in the manufacturing of medical devices such as dental implants, orthopedic implants, and surgical instruments. Sintering is employed to produce biocompatible materials with precise dimensions and mechanical properties suitable for medical applications.

Additive Manufacturing (3D Printing): In some additive manufacturing processes like selective laser sintering (SLS) and binder jetting, sintering furnaces are used to fuse powdered materials layer by layer to create three-dimensional objects. These processes are used in rapid prototyping, custom part manufacturing, and production of complex geometries.

Tool and Die Making: Sintering is utilized in the production of tool and die components for various manufacturing processes. Sintered tool steels and carbides offer high hardness and wear resistance, making them suitable for cutting, shaping, and forming applications in industries such as machining, stamping, and molding.

Additional Processes and Furnace Types

Sintering Furnaces for Metals & Ceramics | Hot Press Furnaces | Combination Debinding and Sintering Furnaces | Brazing, Annealing & Heat Treating Furnaces

Contact Us

800.962.8631

603.595.7233