3600 SERIES

Hot Press Sintering Furnaces

Vacuum and Controlled Atmosphere Hot Press for Powder compaction

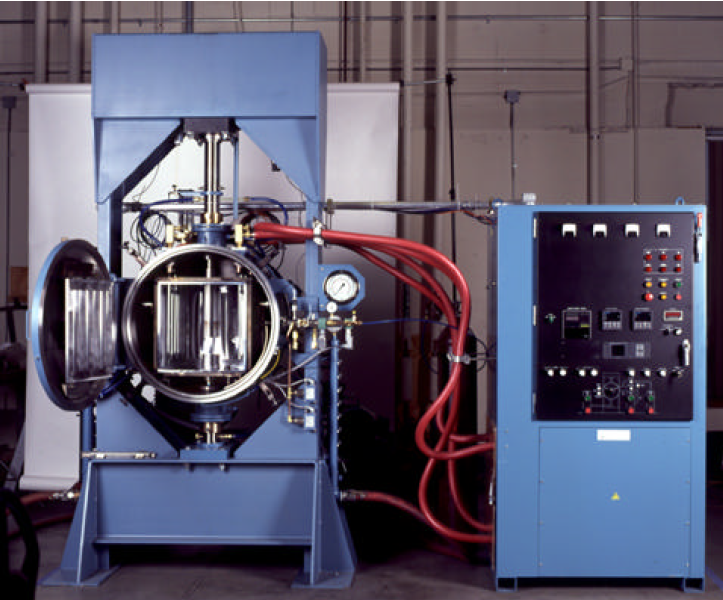

3600 SERIES Hot Press

Centorr/Vacuum Industries’ Hot Press Sintering Furnaces are part of a long standing tradition of quality, dependability, and innovation in high temperature vacuum and controlled atmosphere heating technology.

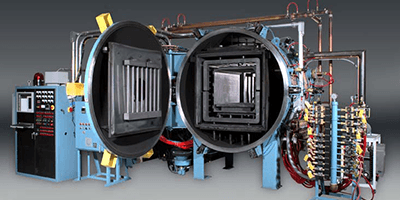

The hot press furnaces’ hot zone is resistance heated (induction systems available), and is thermally insulated from the cold-walled vessel by a multi-layer configuration of metallic radiation shields, or rigidized fibrous graphite insulation. Access to the hot zone for loading/unloading, as well as for routine maintenance and inspection is through the full opening front door. Clamps are provided for operation at slightly positive pressures (up to 2 psig).

Features

- Cold Wall Vacuum furnace design with stainless steel inner/outer jacket & flanges with baffled water cooling.

- Operation to 2552°F (1400°C) metal hot zone, 4172°F (2300°C) graphite hot zone.

- Useable hot zone size 12" (304.8 mm) x 12" (304.8 mm) x 12" (304.8 mm)

- 10" high-speed diffusion pumping system with rotary vane evacuation pump rated to 10-6 torr.

- Programmable digital temperature controller for temperature control to maximum rated temperature of 4172°F (2300°C)

- Temperature control system includes thermocouple with automatic retract system. Two color optical pyrometer provides control from ambient to 4172°F (2300°C).

- Programmable logic controller for dependable valve sequencing.

- Electric motor driven hydraulic pump package rated to 3000 psi for pressing forces to 60 tons.

- Ability to press compacts from 1” (25.4 mm) to 4” (101.6 mm).

- Large, rugged "H-Frame" design with uprights on each side and heavy cross-beams at top and bottom with stiffening gussets for pressing at maximum pressures with minimal deflection.

- Digital Force Controller, directional control valve with pressure transducers and a proprietary "FC-2 Force Control" digital PC card ensures accurate pressing force.

- System designed for quick and easy access to the furnace hot zone for repairs and preventative maintenance.

- Additional sizes and capabilities—please contact us with your requirements. Many additional standard systems available.

Specifications

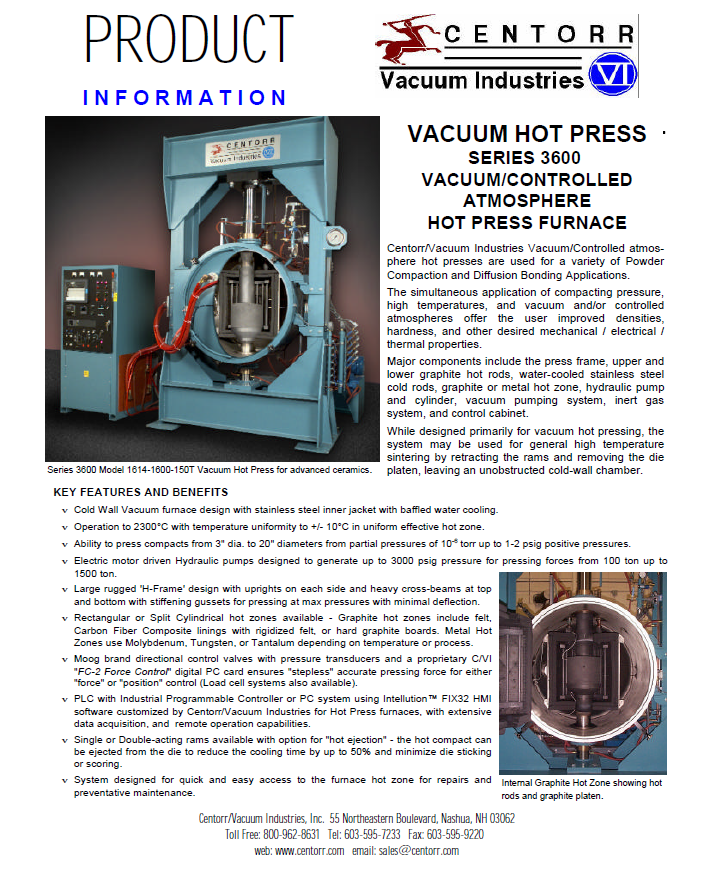

Series 3600 Model 3600-121212-M-M-10A6-A-14-60T

The inside of the furnace chamber conforms to the best vacuum and controlled atmosphere practices, with particular attention given to the surface finish and choice of materials.

Centorr/Vacuum Industries’ Vacuum /Controlled atmosphere multi-purpose hot presses are used for a variety of Power Compaction and Diffusion Bonding, Ceramic Hot Pressing applications.

The simultaneous application of compacting pressure, high temperatures, and vacuum and/or controlled atmospheres offer the user improved densities, hardness and other desired mechanical/electrical/thermal properties.

Major components include the press frame, upper and lower hot rods, water-cooled stainless steel cold rods, graphite or metal interchangeable hot zones, hydraulic pump and cylinder, vacuum pumping system, inert gas system, and control cabinet.

Applications

- Development of ceramic composite materials

- Diffusion Bonding

- Metal Matrix bonding

- Allows compaction close to theoretical densities of most metals and ceramics.

Contact Us

800.962.8631

603.595.7233