PF SERIES

Pusher Furnace

Incorporates a variable speed pusher, optional atmosphere debinding furnace, high temperature sintering furnace, cooling tunnel, load locks, and work box unloading system.

PF SERIES Pusher Furnace

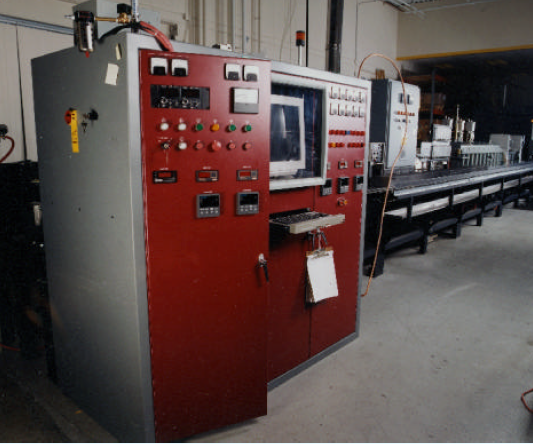

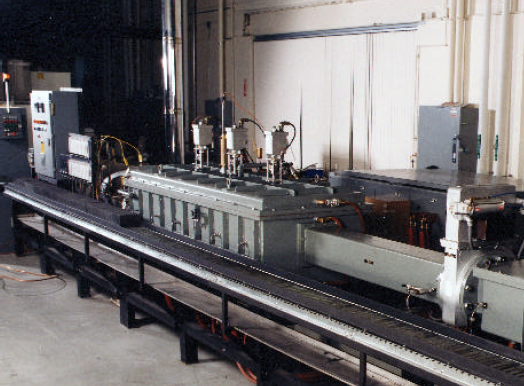

Centorr Vacuum Industries graphite pusher furnace design incorporates a variable speed pusher, optional atmosphere debinding furnace, high temperature sintering furnace, cooling tunnel, load locks, and work box unloading system.

The system is fully integrated for automatic operation with optional conveyor queuing designs. Precision gate valves and proximity switches in conjunction with vacuum load locks ensure a clean oxygen-free environment improving process cleanliness and extending hot zone life.

The hot zone design is specially configured for tight thermal control for solid state and liquid phase sintering. The optional debind zone utilizes a hot wall furnace with alloy retort for binder isolation and removal to a thermal oxidizer for low emissions and clean operation.

Features

- Cold Wall Vacuum furnace design with stainless steel jacket with baffled water cooling.

- Operation to 2500°C. Temperature uniformity to ± 5°C in effective hot zone.

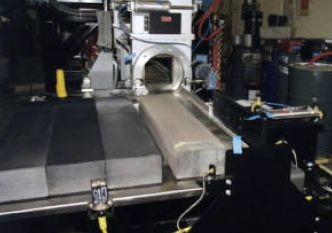

- Vacuum Load locks on entrance and exit tunnels to isolate the chamber during boat loading and unloading.

- PLC with Industrial Programmable Controller or PC system using Intellution™ FIX32 HMI software customized by Centorr/Vacuum Industries for continuous furnaces, with extensive data acquisition, and remote operation capabilities.

- Operation in Inert gas, Hydrogen Process gas, or vacuum environment.

- Two-sided or four-sided graphite heating elements and durable Graphite Board insulation for long hot zone life.

- Cold wall design offers rapid heat up and cool down times (2-3 hours from RT - 2200°C) compared with 3-5 days for heat-up/cool-down of refractory hot wall units.

- Large cycle time reduction translating to excellent throughput. Typical 15 hr "door-to-door" batch furnace cycles can be reduced to 2-4 hr continuous furnace cycles with improved quality.

- The smaller work cross section in a continuous furnace offers minimal thermal inertia compared to large batch furnaces, shortening cycle times.

- Semi-Continuous pusher action or intermittent push designs.

- System designed for quick and easy access to the furnace hot zone for repairs and preventative maintenance.

- SiC, Si3N4

- Carbon-Carbon Composites

- Tungsten Carbide

- MIM components

- BN, ALN

- Alumina

- Tungsten Powders

Optional Features

- CE / VDE / TüV / CSA approvals and other non-U.S. standards for compliance.

- Rigid or Flexible water cooled busswork for improved maintenance and best electrical efficiency.

- Manual rotameter or Mass Flow Controllers for precise, repeatable gas flow.

- Optional Binder Removal System consisting of thermal oxidizer in dedicated debind zone with inner retort designed for durability, ease of replacement and low cost for efficient binder removal.

- Automatic loading and unloading conveyor system with optical proximity switch sensors for notification of work boats exiting the furnace.

- Cold wall designs allows for rapid cold starts, zone temperature adjustments, and fast cool downs providing more flexibility in production planning, product changeover, maintenance planning, and troubleshooting.

- Entry and Exit Load Locks result in safe operation in an inert gas/vacuum environment and reduce the customer's process gas costs compared with systems that flow inert gas out the entrance/exit. tunnels (Process gas requirements are now limited to the amount required to ensure the proper reactions with the raw materials).

Contact Us

800.962.8631

603.595.7233