3720 Series Sintervac AM™ Sintering Furnaces

Sintervac AM™

For the growing market for binder‐jetted 3D printed and Additive Manufactured parts.

Request Quote

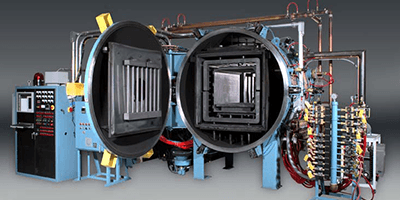

3720 Series Sintervac AM™

The Sintervac AM™ line of vacuum and controlled atmosphere furnaces is Centorr’s newest offering for the growing market for binder‐jetted 3D printed and Additive Manufactured parts.

Originally designed and developed in the early 1970’s for the debinding and sintering of Tungsten Carbide materials with wax or PEG binder systems, the Sintervac AM™ takes this heritage and improves on the proprietary Sweepgas™ binder removal system offering a furnace that can debind in both partial pressures or in positive pressures of Argon, Nitrogen, or Forming Gas depending on the customer’s choice of binders.

The all‐graphite furnace hot zone offers a robust and inexpensive design for processing a variety of stainless steel, tool steel, mild steels and low or high‐alloy materials. With a max temperature of 1600°C it can handle virtually all 3D printed metals on the market today. The graphite insulation is fabricated from durable rigid graphite board secured to an all‐stainless steel jail with CFC hardware in lieu of carbon felt which is more readily deteriorated in a binder‐laden environment. Heating elements use our proprietary tube‐and‐block design comprised of precision‐machined components pinned together with graphite hardware and cured and glued with high‐temperature graphite cement. The horizontal design allows for individual element tubes to be repaired and replaced in‐situ, and out‐perform lower cost designs using graphite ‘slat’ elements bolted to the phase bar which can loosen over time causing micro‐shorts and poor temperature uniformity.

In order to further protect the hot zone insulation and elements, the Sintervac AM™ furnace comes with a tight all‐graphite retort or workbox inside the hot zone which is used to compartmentalize the process offgassing that takes place (in the case of debinding), directing it out of the furnace through a delube manifold plumbed out the bottom of the chamber using our proprietary Sweepgas™ debinding system. The use of a graphite retort allows the binder‐laden gases to exit the hot zone without passing across the heating elements or insulation pack, resulting in longer service life of the hot zone components. The Sintervac® furnace line is available with an optional high‐vacuum pumping systems including a Diffusion pump with cold trap and separate holding pump. A variety of processing environments are available including high/low vacuum and partial and/or positive pressures of Ar, N2, and Forming Gas.

Key Features

- Cold Wall Vacuum furnace design with stainless steel inner jacket and carbon steel outer jackets on the vessel and doors, with rod‐baffled water cooling for long service life. Optional all stainless steel chambers available.

- Available with sealed cooling fan assembly with optional water‐cooled heat exchangers for fast cooling of the load.

- Robust heavy duty graphite tube‐and‐block element design first used over 50 years ago. Compare this with lower cost ‘slat’ element designs bolted together which can come loose during operation at high temperatures causing micro‐shorting and poor temperature uniformity.

- Hot zones use a 30° rule to ensure proper radiation on all sides and 4sided hot zone.

- Operation to 1600°C in vacuum and partial pressures and up to 1450°C in positive pressures of Forming Gas.

- PLC with Industrial Programmable Controller and integrated PC system using Specview® HMI software customized by CVI for vacuum furnaces, with extensive data acquisition; and remote monitoring capabilities.

- G‐10504A Partial Pressure control system (from 1 torr to 15 torr) available for suppression of low vapor pressure compounds and up to 300 torr for debinding, or the included G‐10505A positive pressure Inert gas system for debinding and/or sintering.

- Partial and Positive pressure flexibility offer the ability to handle a variety of carbon‐based binders including methylcellulose, PVA, PVOH, and Phenolic Resin.

- Graphic control panel shows location of vacuum pumps and system status using indicator lamps/icons, and provides for manual operation of the furnace.

Specifications

| STD MODEL* | USABLE SIZE cu. ft. (liters) | EFFECT HOT ZONE WxHxD in (mm) |

|---|---|---|

| AM 100 | 2 (57) | 12 x 12 x 24 (300 x 300 x 610) |

| AM 450 | 4.5 (127) | 18 x 18 x 24 (450 x 450 x 610) |

| AM 500 | 9 (127) | 24 x 18 x 36 (610 x 457 x 914) |

| AM 600 | 12 (255) | 24 x 18 x 48 (610 x 457 x 1220) |

| AM 800 | 16 (453) | 24 x 24 x 48 (610 x 610 x 1220) |

Materials Processed

- Stainless Steels

- Tungsten Carbide

- Tool Steels

- Inconels

Contact Us

800.962.8631

603.595.7233