Tq-Ii Series Rapid Quench Heat Treat

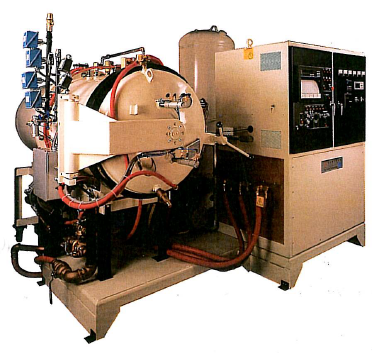

Horizontal 6 Bar Quench Vacuum Furnace

For typical tool room type applications.

Tq-Ii Series Rapid Quench Heat Treat Horizontal 6 Bar Quench Vacuum Furnace

Rated for 90 kg. (200 lb.) normal capacity, the Model 121224-1315-TQ-II vacuum furnace meets high production requirements and provides 2 cubic feet of usable work space to handle a wide variety of part sizes and shapes. The versatility provided by a variety of process control options makes it possible to run partial loads and achieve results comparable to full capacity operation.

Features

- High production

- Two cubic feet of usable work space

- Induction melting furnace chamber

- Capable of running partial loads with results comparable to full capacity operation

- Designed for typical tool room type applications

Specifications

Chamber: cylindrical, steel pressure vessel, carbon steel jacketed, designed for uniform water cooling. Full opening front door. Hot Zone: furnace - molybdenum element with molybdenum/stainless steel insulation, molybdenum posts resting in sockets on the chamber bottom provide sturdy hearth support. Vacuum Pumping System: mechanical booster pumping system, mechanical pump with blower; necessary valving, manifolding and vibration isolation. Temperature Controls, Instruments, Power Supply; NEMA-1 control cabinet with front access door interlocked for safety. Contains: pumping system control panel with pushbutton station and indicating lights, two station thermocouple gauge (1-1000 microns) to main chamber and pump, furnace power control with meters for power supply output (voltage and current on each phase), pushbutton and pilot light for control power and manual power control. Other features: emergency stop button, automatic/manual control for heat mode and quench mode by means of status indicating programmer and three (3) mode controller using control signal from thermocouple, cooling system on/off push-button with pilot light, interlock and failsafe provisions, audible alarm for furnace over-temperature condition, and water flow interlocks to protect critical components. Power Supply: 60 KVA low voltage saturable core reactor, 3-phase balanced; manual circuit breaker with under voltage release for alarm conditions.

Furnace Data

Inert Gas Recirculation System

Internal centrifugal fan (driven by internal 50 hp motor, includes internal heat exchanger).

| Load Capacity: | 90 kg. (200 lb.) |

| Hot Zone Size: | 12 in. wide x 12 in. high x 24 in. deep (300 x 300 x 600 mm) |

| Temperature Range: | Ambient to 1315° C (2400° F) |

| Vacuum Range: | Low micron (10-3 torr range) |

| Quench Press Selectable: | 1-6 bar nitrogen |

| Design Load: | 200 lb. load capacity (50 - 100 lb. typical loads) |

| Hot Zone: | All metal - molybdenum and stainless steel insulation - molybdenum elements and hearth |

Utilities

Space Requirement

Approximately 9 ft. long x 9 ft. wide x 9 ft. high.

| Electrical: | 460 V, 3-phase, 60Hz |

| Water: | 50 GPM @ 40 psig @ 90° F inlet temperature (max) |

| Pneumatics: | 60-90 psig @ .5 scfm, air or inert gas (filtered and lubricated) |

| Inert Gas: | 120 scf @ 100 psig, per furnace cycle, @ 6 bar absolute pressure, @ 5 bar gauge pressure. |

Accessories and Options

- Electrical/Hydraulic Load Cart.

- 55 cubic foot (250 psig) N2 Storage Tank

- Cooling Motor "Soft Start" package

Applications

Designed primarily for typical tool room type applications, i.e. heat treating and quenching. It is the answer to the requirement to process small to medium cross section cold work die steels (S7, A2, D2), conventional high speed steels (M1, M2, M7, etc.) and advanced P/M tooling materials. May be used for other related type operations, i.e., tempering, annealing, brazing, degassing, etc.

Contact Us

800.962.8631

603.595.7233