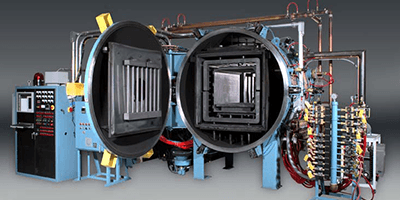

SERIES 3560 Co-Firing Furnaces

Centorr Co-Firing Furnaces are batch type horizontal units designed to provide fully automatic processing of green parts in an accurately controlled, repeatable environment. The furnaces sequentially debinder, sinter, and metallize in one continuous cycle and provide precise, programmable temperature and dew point (atmosphere) control. Typical co-fired materials include alumnia, aluminum nitride, and beryllia. Consistent high quality production is the result.

Features

- Rugged Construction - designed for production environments.

- Automatic and repeatable cycles - fully programmable temperature and dew point control systems for unattended operation.

- Even Temperature Profile - achieved with independently adjustable upper and lower element banks.

- Alarm System - safety interlocks protect against interruption of water, power or gas supply.

- High Purity Production - assured by carbon-free refractory metal construction.

- Regtangular hot zone cross-section - for optimum loading efficiency.

- Efficient Work Handling - front and rear doors for floor-level loading.

Specifications

Summary of Series 3560 Co-Firing Furnace sizes

| Useable Workspace WxHxL, in. (mm) |

Volume Cubic Ft. |

Model Number |

|---|---|---|

| 8 x 8 x 20 (200 x 200 x 500) |

0.74 | 8820 |

| 12 x 12 x 12 (300 x 300 x 300) |

1 | 121212 |

| 12 x 12 x 24 (300 x 300 x 600) |

2 | 121224 |

| 12 x 12 x 36 (300 x 300 x 900) |

3 | 121236 |

| 18 x 12 x 36 (450 x 300 x 900) |

4.5 | 181236 |

| 18 x 12 x 48 (450 x 300 x 1200) |

6 | 181248 |

Typical Furnace Specifications

| Performance Characteristics | Operating temperature: to 2200°C in a full atmosphere of nitrogen or 1900°C in a full atmosphere of hydrogen gas. |

| Vacuum Chamber | Stainless steel interior, fully water jacketed (carbon steel) with baffles for uniform coolant distribution. Full opening, fully jacketed and baffled doors at each end. |

| Hot Zone | Elements: Rugged molybdenum or tungsten rod elements arranged in uppoer and lower banks with power independently adjustable to provide optimum uniformity; surround work on four (4) sides. |

| Thermal Insulation | Heat shields retained in removable stainless steel frame. Work Support: 1/4" x 2" hearth rails mounted in posts firmly supported at chamber. |

| Dew Point Control System | Stainless steel bubbler with thermostat control and electronic water level control. Dew point level is controlled by blending wet and dry gas. Gas lines are heat traced to prevent condensation. Varying dew points are automatically programmed with a DSP700 programmer/controller, hygrometer, and automatic valves. |

| Hydrogen System | Model G10503A flow through process gas system, contains extra door clamps, pressur relief ports, automatic purge system, and necessary interlocks for safe operation. |

| Pumping System | Mechanical pump with manifold, automatic valve. |

| Power Supply | Variable reactance type with 3-phase input, trimming for upper and lower element banks. Rigid, water-cooled buss connection to furnace electrodes. |

| Controls and Instruments | NEMA-1 cabinet containing microprocessor-based programmer/controller (Honeywell DCP700). Data logger for temperature and pressure (Honeywell DPR1500). Over-temperature protector with separate type W5 thermocouple. Ammeters and voltmeters for each power supply output phase, push-buttons and pilot lights, alarm panel for safety interlocks on all critical circuits. |

| Utility Requirements | Electrical: 460/3/60 Water: 30-50 psig; 60-70°F Compressed Air: 80-100 psig, filtered and lubricated. |

| Accessories | Fork lift load truck, manual operation with electro-hydraulic lift, guides and stops on truck and furnace. |

Contact Us

800.962.8631

603.595.7233