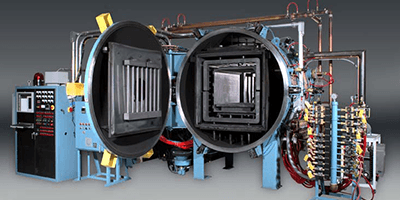

3400 SERIES TOP OR BOTTOM LOADER

High Vacuum Batch Furnaces

Vertical top/bottom loading high vacuum batch furnaces for heat treating and annealing.

Series 3400 Vacuum Furnace Description

The Series 3400 vacuum furnace design is Centorr Vacuum Industries production oriented offering for a variety of heat treatment and annealing applications. The basic design comprises a multi‐zone working hot zone available in lengths from 3‐10 meters, rated from 900°C to 1315°C max temperatures. A long list of optional equipment makes this one of the most versatile custom designed furnaces available today. The "top‐loading" design uses electric loading cranes to lower customer loads up to 2000kgs in size, and offers better ergonomics for materials that must be fired in an upright orientation.

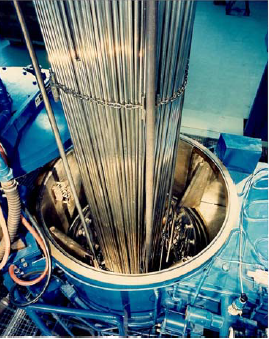

The Series 3400 furnace line contains features only found on high-end heat treat furnaces, such as a stainless steel interior vacuum chamber, heavy duty Nichrome ribbon heating elements; and all‐metal SS radiation shields for high‐vacuum and low contamination, resistance to oxidation, fast heating and cooling, and excellent process cleanliness. You won't find any refractory ceramic insulation or graphite felt/board in this hot zone.

Standard Furnace instrumentation includes a programmable controller with PLC for process control. Name brand vacuum sensors and gauges are available on all systems as well as analog/ digital chart recorders. A full complement of program interlocks and safeties ensures safe and efficient furnace operation and reduces the chance of operator vacuum pumping errors.

The Series 3400 furnace line is available with high‐vacuum pumping systems utilizing primarily Diffusion pumping systems, with or without cold traps and refrigerated baffles. With over 20 units in the field, the Series 3400 design is one of the most proven production designs for heat treating and annealing furnaces worldwide.

Features

- Cold Wall Vacuum furnace design with stainless steel inner jacket and mild steel outer jackets with baffled water cooling.

- No epoxy coated surfaces on chamber interiors results in higher vacuum integrity.

- Heavy duty Nichrome ribbon elements used instead of thin strip or foil elements which can be easily damaged. Hot zones use a 30° rule to ensure proper radiation on all sides. Moly rod elements used for higher temperature designs.

- Operation to 900°C with six‐sided heating elements high‐vacuum or partial pressures of Argon.

- PLC with Industrial Programmable Controller or PC system using Intellution™ FIX32 HMI software customized by CVI for vacuum furnaces, with extensive data acquisition; and remote operation capabilities.

- High and low vacuum pumping systems including diffusion pumps with refrigerated or Polycold style baffles. Mechanical rotary piston pumps and Roots style blowers.

- G‐10504A Partial Pressure control system (1‐1000 microns) available.

- Graphic control panel shows location of vacuum pumps and system status using indicator lamps, and provides for manual operation of the furnace.

- Robust fan cooling system with optional water‐cooled heat exchanger for fast cooling cycles.

- Integrated water cooling piping with color‐coded hoses.

- Analog Ammeters and Voltmeters on control cabinet for each leg of the power supply for operator feedback.

- Customized loading systems and fixturing available optionally upon request.

- Suitable for processing Stainless Steels, Inconel 600 and 690, Zirconium alloys, Ti, Nickel, and Superalloys.

Specifications

Options

- Integrated cooling fans available with or without integral heat exchangers.

- CE and NFPA approval standards for compliance available.

- Rigid or Flexible water cooled busswork for improved maintenance and best electrical efficiency.

- Chambers constructed of stainless steel interiors to provide improved vacuum pumping performance when compared to mild steel epoxy coated chambers.

- Cylindrical chamber are structurally more sound, avoiding the multiple welds and resultant stresses inherent in a rectangular chamber.

- Pneumatic style door arrangement swings out of the way for fast and efficient loading.

- Integrated water flow indicators/flow switches with low water alarm setpoint for safe operation.

Applications

- Heat treating

- Annealing

Contact Us

800.962.8631

603.595.7233