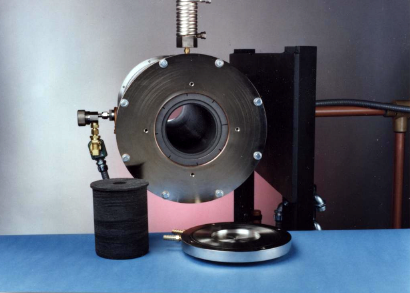

10 SERIES Graphite Tube Furnace

The Centorr Vacuum Industries Model 10 High Temperature Vacuum or Controlled Atmosphere, Cold Wall, Graphite Tube Furnaces are simple and easy to operate.

A typical Furnace System consists of the Basic Furnace Chamber Assembly, the Evacuation System, the Process Gas System, the Power Supply System, the Temperature Control Instrumentation, and the Furnace Mounting Assembly.

These furnaces can be built having Effective Heat Zone Sizes of 2.4" ID x 4" to 14" Long or 4" ID x 6" to 16" Long; and capable of operating up to 2750°C (4982°F) in Vacuum, Inert Gas, Nitrogen (or in Oxidizing Atmospheres with Muffle Tube Kit).

The Evacuation Kit is capable of attaining 10-50 Microns; the furnace chamber may be backfilled to 2 PSIG.

The Furnace chamber is usually mounted on a stand with the Evacuation System located directly behind for maximum efficiency. The Power Supply/Control Console is also located as close as possible to the furnace chamber.

The Furnace is ready to operate as soon as power is connected to the Circuit Breaker, and water inlet and drain connections are made.

Prior to shipment, the Furnace is completely assembled and thoroughly tested; a copy of test results will accompany shipment.

Learn about how Graphitization Furnaces are Powering the Future of Advanced Carbon

Features

- Low initial cost

- Efficient, inexpensive to operate

- Uncomplicated design, easy to operate

- Clean, compact, vacuum tight construction

- Use in vacuum, inert, reducing or oxidizing atmospheres

- Good Accurate temperature control

Specifications

| HEAT ZONE SIZES | OPERATING TEMPERATURE |

|---|---|

| 2.4" ID x 4" to 14" Long | Up to 1000°C (2012°F) |

| 4" ID x 6" to 16" Long | 1650°C (3000°F) 2000°C (3632°F) 2500°C (4532°F) 2750°C (4982°F) |

| OPERATING PRESSURE | |

| 10-50 Microns to 2 PSIG |

Applications & General Info

Applications- Annealing

- Carbon Fiber Processing

- Ceramic Firing

- Heat Treating

- Homogenization

- Melting

- Sintering

- Wetting Studies

BASIC FURNACE CHAMBER ASSEMBLY

The Basic Furnace consists of a double wall all stainless steel (304L), water-jacketed chamber, inside of which is the Heat Zone. The Heat Zone is resistance heated. The Heating Element is made of Solid Graphite. Heat shielding is by Graphite Felt pressed into solid form. Heat zone components are readily accessible for inspection or maintenance.

The entire inside of the furnace chamber is designed to conform to the best High VacuumPractice. Particular attention is given to the choice of heat zone materials and to surface finishes. Ports are provided for Sighting, Thermocouples, Evacuation, Inert Gas inlet and exit, Gauges, etc. CENTORR's proprietary Rotatable Sight Window with gas port is included as standard equipment.

Loading is done through easily opened lids at either end of the Furnace Chamber. Lids are held in place by screws which permit operation to slightly above ambient pressure.

EVACUATION SYSTEM

For operation in the 10-50 Microns range of vacuum or for evacuation prior to backfilling with Inert Gas or Nitrogen, we include an Evacuation System. This includes a Mechanical Vacuum Pump, Vacuum Valve, and Manifold. Line Filter ahead of the vacuum pump, and Thermocouple type Vacuum Instrument are optionally available.

PROCESS GAS SYSTEM

Process Gas Systems consist of Vacuum tight Gas Inlet Valve and Relief Valve, Bourdon type Pressure Vacuum Gauge, and Manifold.

POWER SUPPLY SYSTEM

Power Supply Systems consist of Silicon Controlled Rectifier Power Controller (Saturable Core Reactors also available) with Current Limit, Stepdown Transformer, Circuit Breaker, Contractor, Control Transformer, Ammeter, Voltmeter, Push Buttons, Indicator Lights, Water Interlocks, all completely wired and packaged in an attractive floor standing cabinet.

Utility requirements are given in KVA at customer's Primary Voltage, Single or Three Phase, and 50 or 60 Hertz.

OPTIONS - MUFFLE TUBE KIT

For Operating in Oxidizing Atmospheres, these furnaces can be supplied with a Refractory Muff to the furnace at both ends. Muffle tube kits can also be provided with closure lids with ports for gas inlet and exit, and/or sight windows or thermocouples.

Contact Us

800.962.8631

603.595.7233