LF G SERIES Graphite Hot Zone

Centorr's Series LF Top Loading Multi-Purpose furnaces are available with a high temperature vacuum or controlled atmosphere Graphite Heat Zone. With a Graphite Heat Zone, this vertical furnace is used for vacuum or controlled atmosphere heat treatment of ceramics, graphite and carbon composites, reactivity studies, and small scale sintering studies.

A typical furnace is made up of a double-walled, water-cooled 304L stainless steel chamber with water-cooled, hinged lid, a hot zone with a graphite element and rigidized fibrous graphite insulation, a power supply, temperature sensor, controller and over-temperature controller with hot zone interlock.

Features

- Operation to 3000°C

- Double-walled, water-cooled 304L stainless steel chamber

- Digital programmable temperature controller with auto-tuning

- Stainless steel chamber, with graphite hot zone.

- Power supply with current limiting, and soft start features fully interlocked for failsafe operation.

Series LF with Graphite Heat Zone shown above.

Series LF Graphite Heat Zone

Specifications

PERFORMANCE SPECIFICATIONS (Empty Furnace)

Operating Temperature: 2450°C (4442°F) in vacuum (150 m Torr); 3000°C (5432°F) in Argon/Noble gas blend, Nitrogen Gas.

Operating Pressure: 2 PSIG (0.14 KG/SQ. CM) positive pressure to 10-2 Torr range

Ultimate Vacuum: Standard Roughing Pump Model - 10-2 Torr range (chamber clean, cold, empty and out-gassed).

Heat Up Time: 21°C to 3000°C (69.8°F - 5432°F), Approximately 150 minutes

Cool Down Time: 3000°C to 100°C (5432°F - 212°F), Approximately 230 minutes

PRICE (Subject to Change)

Standard Mechanical Pump Model: Contact factory for current pricing

SHIPMENT

1 month from Purchase Order*

DETAILED EQUIPMENT SPECIFICATIONS

| Chamber: | Double-walled, water-cooled 304L stainless steel chamber with water-cooled 304L stainless steel hinged lid. | |

| Hot Zone: | 4" (76.2 mm) dia. x 5" (127 mm) high graphite element with rigidized fibrous graphite shields. | |

| PUMPING SYSTEM ALTERNATIVES | ||

| Roughing Pump Vacuum System: | Manual vacuum system with VRL 902111 vacuum gauge, Vacuum Research Corp. Model 200-7, 200 L/in. @ 60 Hz (7.0 CFM) direct drive mechanical pump (or equal) and all necessary plumbing and manifolding. | |

| Power Supply: | 18 KVA SCR controlled with current limiting and soft start features-fully interlocked for failsafe operation. | |

| Temperature Sensor: | (1) Two-color optical pyrometer. | |

| Controller: | Eurotherm 2416 temperature controller/programmer. 1/16 DIN temperature controller, 4 programs of 16 segments, auto-tune, RS-485 communications. | |

| Overtemperature Controller & Hot Zone Interlock: | Eurotherm 2216E overtemperature controller. 1/16 DIN temperature controller & hot zone interlock. RS-485 communications. | |

| Furnace Cabinet: | Combination furnace, power supply, temperature control instrumentation, vacuum instrumentation, manually operated valving, enclosed in a painted steel cabinet. | |

| UTILITIES REQUIRED | |||

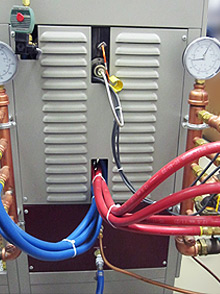

| Electrical: | 21.7 KVA, 220V/1PH/50-60 Hz, 98 Amps Total. Connected load, 125 AMP Circuit |  Easy to Connect Water and Gas Connections (typical)

Easy to Connect Water and Gas Connections (typical) |

|

| Water Supply: | 3 GPM at 70°F (21°C) max. 40 PSIG Max. pH not to exceed 8.5. Conductivity not to exceed 400 micro MHOS (Micro Siemens) 1" NPTF supply connection. | ||

| Water Return: | 20 PSIG (1.4 Bar) Max. back pressure 1¼" NPTM drain connection | ||

| Inert Gas: | Argon, Nitrogen, or 4% H2/96% N2, approximately 0.2 cubic feet per backfill to atmospheric pressure, regulated at 10 PSIG. ¼" NPTF inlet connection ¼" NPTF exhaust connection | ||

| Pump Exhaust: | ¾" (19.0 mm) ID Hose connection | ||

| Air Supply: | 80 PSIG. ¼" NPTF connection | ||

TERMS & CONDITIONS

Payment with Purchase Order FOB: EX-WORKS (CVI Manufacturing Facility, Nashua, NH USA) CVI Standard Terms and Conditions, Form TC-2000 *Shipment Dependent on Factory Loading at Time of Order

WARRANTY

Warranty, Manuals, Checkout and Field Service Warranty, Form C/VI-107

CRATING INFORMATION

60" (152.4 CM) Long X 60" (152.4 CM) wide X 75" (190.5 CM) high 1600 Lbs. (725.7 kg)

Contact Us

800.962.8631

603.595.7233