CA SERIES Transparent Furnaces

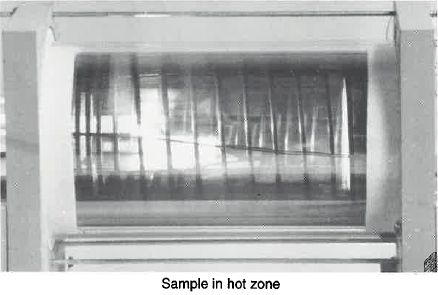

Don't wait for your furnace to cool to monitor your process. With the unbeatable view into CA Series Transparent Furnaces, you observe and adjust the process as it occurs!

APPLICATIONS

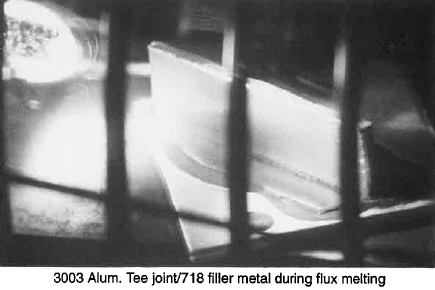

- Pre-production batch testing of flux, filler metal, and clad materials for melting range, etc.

- Optimizing joint design

- Define optimum production process cycles

- Analyzing problems in production furnaces (duplicate temp, dew point, vacuum level, and process cycle)

- Education and training

Ask for our free videotape

Features

- Increase insight into process

- don't guess, see what occurs at temperature

- don't miss transient phenomena

- Accelerate development

- fewer runs required to develop process

- up to 8 typical braze cycles per day

- Save time, process gas, and energy

- fewer runs, less energy per run

- Rapid heating and cooling rates

- reduced cycle time

Specifications

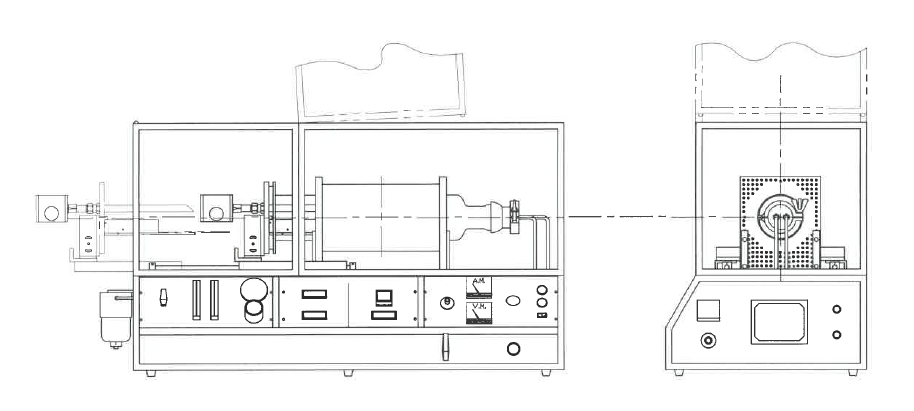

CA2091 Transparent Furnace

(computer control system not shown)

| CA2090 | CA2091 | |

|---|---|---|

| Hot Zone Size | 2.5" dia x 5" long | 4.5" dia x 10" long |

| Temp Rating | To 950°C (1742°F) | To 950°C (1742°F) |

| Atmosphere | N2, Ar, He Forming Gas | N2, Ar, He Forming Gas |

| Vacuum (optional) | 5x10-6 | 5x10-6 |

| Power | 115VAC, 1¢, 30A | 115VAC, 1¢, 30A |

| Gas | 20-0 psi, 20 scfh | 20-0 psi, 20 scfh |

| Bench Space (plus computer) | 48"W x 30"D x 46"H (1219 x 762 x 1168 mm) | 60"W x 30"D x 46"H (1524 x 762 x 1168 mm) |

| Weight | 120 lbs. | 150 lbs. |

Contact Us

800.962.8631

603.595.7233