60 SERIES

Front Access Furnace

The flexible solution for high-temperature vacuum or controlled atmosphere operation.

60 SERIES Front Access Vacuum Furnace

Centorr Vacuum Industries’ Model 60 Front Access Furnace is part of a long-standing tradition of quality and dependability in high temperature, controlled atmosphere heating technology.

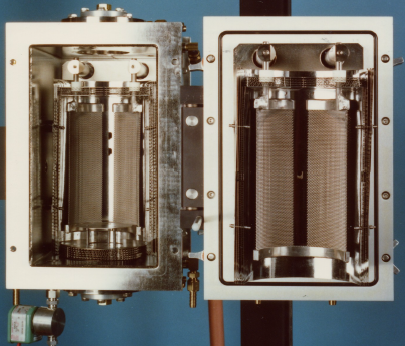

The Model 60’s cylindrical hot zone is resistance heated (up to 3000°C), and is insulated from the cold wall by a multi-layer configuration of metallic radiation shields or rigid graphite insulation.

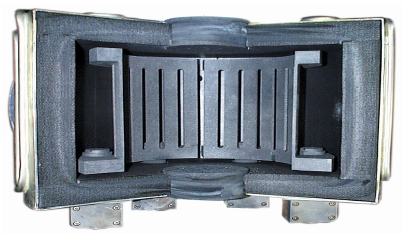

Access to the hot zone for loading and unloading, as well as for routine maintenance and inspection, is through the full-opening front door. Clamps are provided for operation to slightly positive pressures.

The inside of the furnace chamber conforms to the best high-vacuum practices, with particular attention given to surface finish and choice of materials. The design and construction of high quality vacuum furnaces calls for minimizing component surface area and potential leaks; thus, you won’t find inferior materials, or internal coolant connections in a Centorr Vacuum Industries’ Model 60 furnace.

Visual observation of the specimen is provided by a sight port equipped with the Centorr Vacuum Industries’ designed rotatable viewing glass. Ports are also provided for inert gas inlet, thermocouples, gauges, and other pertinent instrumentation.

Features

- Affordable research and development tool

- Accurate and uniform temperature control

- For multiple uses

- Interchangeable metallic or graphite hot zones

- Clean, compact, vacuum-tight construction

- Operates in vacuum, inert, or reducing atmospheres

- Low thermal mass means rapid heating and cooling

- Double-walled, stainless steel furnace chamber

- User-engineered for easy operation; only minimal training required

- Attractive and convenient console design; appearance will complement any facility

Specifications

| HEAT ZONE SIZE: | TEMPERATURE: | PRESSURE VACUUM: |

|---|---|---|

| Inside Diameter: 2.5" to 12" (63.5 mm to 304.8 mm) |

Up to 2000°C

2500°C 2750°C 3000°C |

2 PSI (0.14 Kgs/Cm2) to 10-6 Torr |

GENERAL DESCRIPTION

The Centorr Vacuum Industries Series 60 High Temperature Vacuum or Controlled Atmosphere, Front Access, Cold Wall, Refractory Metal, Laboratory Furnaces are simple and easy to operate.

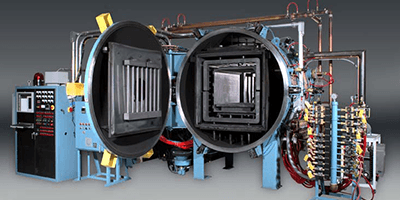

A furnace system typically consists of the Basic Furnace Chamber Assembly, the High Vacuum System or Evacuation System, the Process Gas System, the Power Supply, the Temperature Control Instrumentation, and the Furnace Mounting Assembly.

The unit is ready to operate as soon as power is connected to the main circuit breaker, and water inlet and drain connections are made.

The Furnace is completely assembled and thoroughly tested prior to shipping; a copy of test results will accompany shipment.

BASIC FURNACE CHAMBER ASSEMBLY

The Basic Furnace consists of a double wall all stainless steel (304L), water-jacketed chamber, inside of which is the Heat Zone. The Heat Zone is resistance heated. The Heating Element is made of Tungsten, Tantalum, Molybdenum, or Kanthal. Heating shielding is by concentric layers of metallic radiation shields. Heat zone components are readily accessible for inspection or maintenance. Provision is made for either suspending the work from above or for support by means of a work support hearth.

The entire inside of the furnace chamber is designed to conform to the best High Vacuum practice. Particular attention is given to the choice of heat zone materials and to surface finishes. Ports are provided for Sighting, Thermocouples, Evacuation, Inert Gas inlet and exit, Gauges, etc. Centorr Vacuum Industries’ proprietary Rotatable Sight Window is included as standard equipment.

Loading is done through the front door. Clamps are provided for operation to slightly above ambient pressure.

HIGH VACUUM SYSTEM

For operation in the 10-4 - 10-6 torr vacuum range of vacuum we supply a High Vacuum System. This system includes a High Speed Diffusion Pump, Cold Trap, Mechanical Pump, High Vacuum, Foreline, and Roughing Valves, Vent Valves, High Vacuum Elbow, and Vacuum Instrument. Systems can be fully Automatic, Semi-Automatic, or simply Manual.

PROCESS GAS SYSTEM

Process Gas System consists of Vacuum tight Gas Inlet Valve and Relief Valve, Bourdon type Pressure-Vacuum Gauge and Manifold.

POWER SUPPLY SYSTEM

Power Supply Systems consist of Silicon Controlled Rectifier Power Controller (Saturable Core Reactors also available) with Current Limit, Step-down Transformer, Circuit Breaker, Contactor, Control Transformer, Ammeter, Voltmeter, Push Buttons, Indicator Lights, Water Interlocks, all completely wired and packaged in an attractive floor standing cabinet.

TEMPERATURE CONTROL INSTRUMENTATION

Centorr can supply from the simplest Manual Power Control to the most elaborate instrumentation. This can include Automatic closed loop control utilizing Thermocouples, Power Transducers, or Optical Pyrometers for sensing; and incorporating Indicators- Controllers, Recorders, and Programmers. Various types of Micro-Processor Programmers are now available and extremely popular.

Contact Us

800.962.8631

603.595.7233