All Series

Hot Pressing Furnaces

Eliminate the need for binders in manufacturing processes and uses the combination of force and temperature to bond parts completely.

Request Quote

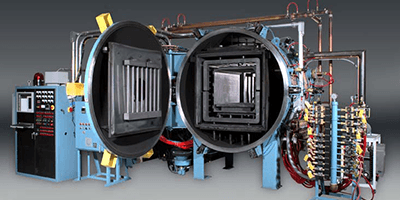

Hot Pressing Furnaces

Hot pressing involves the combination of added force during the sintering of high-temperature materials either in vacuum or a positive pressure of inert gas. This pressure on the compacted powder aids in the increased densification of the material resulting in a billet of material with densities close to theoretical.

Hot Pressing for Durable and Tight Bonds

In diffusion bonding applications, two dissimilar metals are placed in close proximity and then compressed under the combination of high-vacuum and heat, to ‘weld’ the materials together forming a durable and tight bond.

Eliminate the Need for Binders in the Manufacturing Process

Both styles of hot press furnace have both hot and cold rods for applying pressure and use either graphite punches and dies for holding the parts, or use pressing platens to exert the force during diffusion bonding.

By using the hot pressing technique, customers can eliminate the need for binders in their manufacturing process and instead use the combination of force and temperature to bond their parts completely.

Hot Pressing Furnaces are Used in a Variety Of Industries

Centorr Vacuum Industries provides hot pressing furnaces used in many varied industries. Typical industries that use hot press furnaces include:

-

- Aerospace Parts Manufactures

- Diffusion Brazing OEM’s

- Advanced Ceramics Parts Manufacturers

- Body and Vehicle Armor Manufacturers

Available Hot Press Furnaces

Centorr’s hot press designs range from small laboratory size units to larger production size furnaces.

-

- View Centorr's Vacuum Hot Press Furnace models

Additional Processes and Furnace Types

Sintering Furnaces for Metals & Ceramics | Hot Press Furnaces | Combination Debinding and Sintering Furnaces | Brazing, Annealing & Heat Treating Furnaces

Contact Us

800.962.8631

603.595.7233