Transforming Carbon Into High-Performance Graphite

Graphitization furnaces take ordinary carbon materials and turn them into something extraordinary: ultra-pure, crystalline graphite. Operating at temperatures up to 3,000°C, these furnaces unlock the properties that industries depend on—exceptional strength, thermal stability, and superior conductivity.

Why It Matters

From the lithium-ion batteries in electric vehicles to the carbon-carbon composites used in aerospace, today’s most advanced technologies rely on materials that only graphitization furnaces can deliver. With precision heating, controlled atmospheres, and modern automation, these systems ensure consistent, high-quality results.

Where They’re Used

- Semiconductors: Graphite components for reliable, high-purity production.

- Aerospace & Defense: Heat-resistant carbon composites for critical applications.

- Energy Storage: Graphite anodes that power the next generation of EVs.

- Metallurgy & Nuclear: High-strength graphite electrodes and reactor components.

The Advantages

- Ultra-High Purity Materials for demanding industries

- Superior Conductivity & Strength for performance under extreme conditions

- Scalable Solutions from research to mass production

- Proven Reliability through advanced monitoring and controls

The Future of Graphite Manufacturing

As demand for cleaner energy, advanced electronics, and sustainable transport grows, so does the need for high-performance carbon. Graphitization furnaces are the backbone of this transformation—delivering the precision, purity, and scalability that modern industries require.

Graphitization isn’t just a process. It’s the foundation of innovation.

Learn About Centorr's Graphitization Furnaces:

- Continuous Furnaces: These furnaces allow for the continuous processing of materials, making them suitable for large-scale industrial applications.

- Batch Furnaces: These are used for processing smaller quantities of material, where the material is placed in the furnace in batches.

- Laboratory Furnaces: Smaller-scale furnaces used for research and development purposes.

| Product Series | Furnace or Equipment Type | Applications/Processes | Max Temp. |

|---|---|---|---|

| 10 | Graphite Tube Furnace | Annealing, Carbon Fiber Processing, Ceramic Firing, Heat Treating, Homogenization, Melting, Sintering, Wetting Studies | Up to 2750°C (4982°F) |

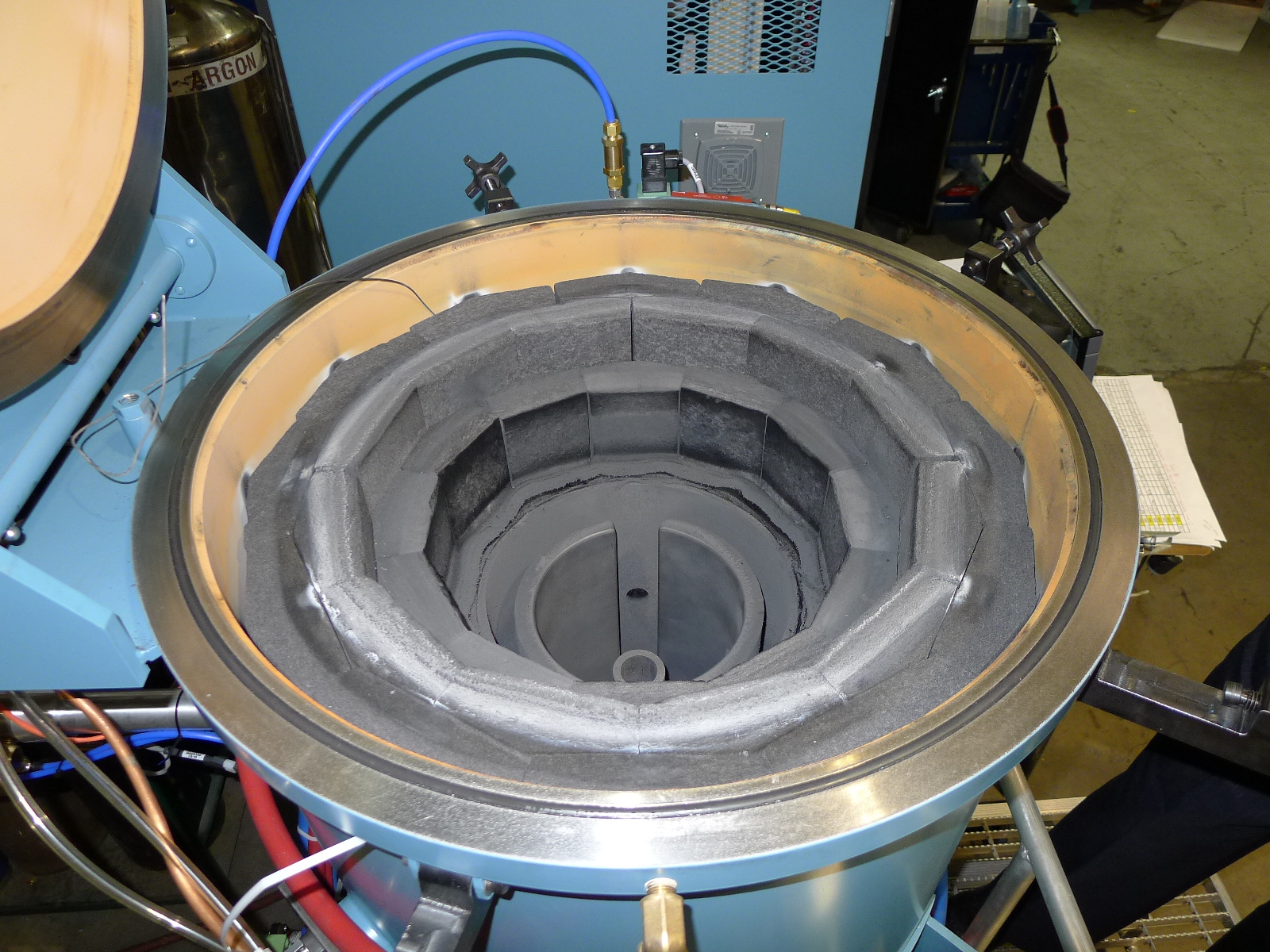

| 45 | Top Loading Graphite | Annealing, Brazing, Crystal Growth, Ceramic Firing, Degassing, Heat Treating, Melting, Sintering. | 3000°C (5432°F) |

| 46 | Bottom Loading Graphite | Annealing, Brazing, Crystal Growth, Ceramic Firing, Degassing, Heat Treating, Melting, Sintering. | 2800°C (5072°F) |

| LF Graphite Hot Zone | Top Loading Furnace | Multi-purpose | up to 3000°C (5432°F) |

| Series 4300 Heat Treat Furnaces | Top Loading Furnace | Graphitization and CVI | Up to 2900°C (5252°F) |

Contact Us

800.962.8631

603.595.7233