All Series

Brazing, Annealing and Heat Treating Furnaces

Centorr’s line of refractory metal hot zone high-vacuum furnaces provide furnace solutions to the aerospace, automotive, and medical industries.

Request Quote

Brazing, Annealing and Heat Treating Furnaces for 50 Years.

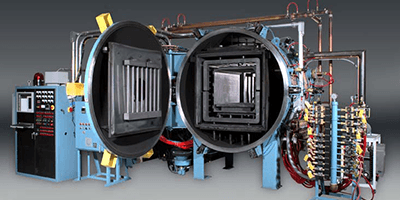

Today’s manufacturers of precision components for the aerospace, automotive, and medical industry rely on high-vacuum furnaces for processing their materials as it provides one of the cleanest atmospheres possible.

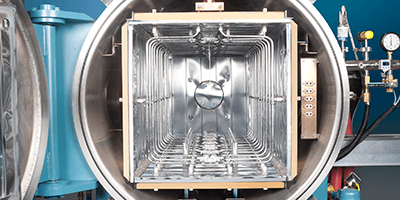

Centorr’s line of refractory metal hot zone high-vacuum furnaces have provided a solution to these industries for the past 50 years. Our brazing, annealing and heat treating furnaces allow for the heat treating and annealing of stainless and superalloy materials, yielding bright and shiny parts after treatment.

Heat treating is typically used to impart specific properties to the base material and can improve the hardness or relax stresses that are inherent in its original manufacturing process. This is critically important for materials in the nuclear industry where oxidation and discoloration of the parts is not acceptable.

In brazing applications, a braze filler metal (or BFM) is placed between two different parts allowing them to fuse together at high temperatures in high-vacuum forming an incredibly tight bond without the need for applied pressure.

Brazing, Annealing and Heat Treatment Furnaces are Used in a Variety Of Industries

Centorr Vacuum Industries provides brazing, annealing and heat treatment furnaces that used in many varied and critical industries. Typical industries that use hot press furnaces include:

-

- Aerospace Industry

- Precision Components Manufacturers

- Medical Equipment Manufacturers

- Advanced Ceramics Parts Producers

Available Brazing, Annealing and Heat Treatment Furnaces

Centorr’s offers a wide range of furnaces to suit your needs.

-

- View Centorr's smaller Laboratory Furnace models

- View Centorr's larger Production Workhorse models

Additional Processes and Furnace Types

Sintering Furnaces for Metals & Ceramics | Hot Press Furnaces | Combination Debinding and Sintering Furnaces | Brazing, Annealing & Heat Treating Furnaces

Contact Us

800.962.8631

603.595.7233