CENTORR VACUUM INDUSTRIES SELLS THREE SILICON CARBIDE FURNACES FOR HIGH-TEMPERATURE SINTERING

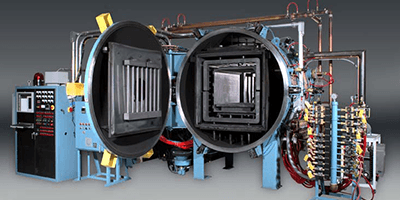

December 2004 - Nashua, NH -- Centorr Vacuum Industries announced it has received orders for three Silicon Carbide sintering furnaces for 2005 delivery from various customers.

These new furnaces build on the success of CVI's experience in non-oxide ceramics and Tungsten Carbide hardmetals with modifications made specifically for higher-temperature SiC processing.

Centorr's design includes robust Graphite Tube and Block elements designed for use to 2300°C, with single or multiple zones of control for excellent temperature uniformity. The insulation package has been upgraded from common felt to a rigid graphite board (with or without CFC covering) for long-term service even in the presence of process off-gassing or binder contamination. CVI's standard Binder Removal System (BRS) uses positive pressure flowthrough gas and includes a binder reservoir with integrated exhaust tower. For larger designs, the new dual flowthrough Sweepgas™ system provides inert gas to both the chamber and retort ensures proper "sweeping" away of binders using preheated inert gas and minimum condensation of binder residue on the cold chamber walls. For complete binder destruction, instead of trapping, the larger furnace utilizes 1000°C heat for complete destruction of VOC's and the virtual elimination of offending exhaust byproducts. This proven system allows one furnace to accomplish two individual processes (binder removal + sintering), saving floor space, money, and maintenance costs for two separate pieces of capital equipment. Furnace control is via PLC/Programmable Controllers or Centorr's in-house custom designed HMI visualization interface using award-winning Intellution® software. This event-based control offers extensive data acquisition functionality for supporting SPC and continuous improvement programs, and remote system operation.

The new Sintervac SiC is available in sizes from 2,3, 4.5, 9,16,24, and 25 cubic foot volumes.

Centorr Vacuum Industries is a high temperature vacuum / controlled atmosphere furnace manufacturer with an installed base of over 6000 units worldwide. Their furnace offering ranges from large commercial and production units with hot zones over 3m x 3m, to smaller Lab and Research & Development furnaces for use at temperatures over 3000°C. They are located in Nashua, NH with a fully staffed Aftermarket Field Service group, and Applied Technology Center offering R&D support and toll production service. For more information please contact Scott K. Robinson at 603-595-7233 x 257.

Contact Us

800.962.8631

603.595.7233