Centorr Vacuum Industries

Benefits

THE BENEFITS OF CVI VACUUM FURNACES

Centorr Vacuum Furnaces has been manufacturing vacuum furnaces since 1954. Over the years, we have developed unparalleled expertise in the design and manufacturing of furnaces:

-

- Metal Injection Molding

- Powdered Metal processing

- Heat Treatment

- Vacuum Induction Systems for Carbon/Graphite Systems

- Annealing, and Brazing Equipment.

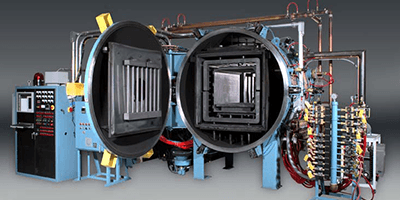

CVI has the most advanced vacuum furnace technology in the world and our furnaces are used in various industries, including aerospace, medical, energy, and automotive, for processes such as heat treating, brazing, sintering, and diffusion bonding. CVI furnaces are known for their advanced technology and precise control of temperature and atmosphere conditions. Different vacuum furnace models and configurations are available to meet specific customer requirements.

Some of the many benefits of Centorr Vacuum Furnaces include:

-

- High Vacuum Capability: Our furnaces can achieve high levels of vacuum, typically in the range of 10^-5 to 10^-6 Torr, ensuring clean and contamination-free processing environments.

- Temperature Control: Centorr Vacuum Furnaces are designed to achieve and maintain high temperatures, often exceeding 2000°C (3632°F). They offer precise and uniform temperature control, allowing for consistent results.

-

- Atmosphere Control: CVI vacuum furnaces can operate under a controlled atmosphere, such as inert gas or reactive gas, to accommodate various processes and materials.

- Versatility: Centorr Vacuum Furnaces are versatile and can be used for a wide range of applications, including annealing, hardening, tempering, and stress relieving of metals and alloys.

- Advanced Heating Elements: CVI furnaces utilize state-of-the-art heating elements, such as graphite or refractory metal, to achieve rapid heating rates and efficient energy transfer.

-

- Process Monitoring and Control: The furnaces are equipped with advanced control systems that monitor and regulate key parameters like temperature, pressure, gas flow, and cooling rates. This ensures precise process control and repeatability.

-

- Strong Background in Automation and Controls, Inert and Process Gas Systems; and process knowledge comes from decades of sintering a variety of Metals and Non-Oxide Ceramics materials.

-

- Extensive Debinding Experience: With over 300 different binder systems for metals and ceramics processes, using trapping, condensation, or thermal destruction techniques.

-

- Safety Features: Centorr Vacuum Furnaces are designed with safety in mind. They incorporate features like interlocks, emergency shutdown systems, and comprehensive thermal insulation to protect operators and the surrounding environment.

INDUSTRY DESIGN AND INNOVATION LEADERSHIP

Centorr Vacuum Industries' Is a leader in vacuum furnace design and manufacturing. This leading position has been achieved through high quality engineering and manufacturing for the application fields served. CVI has been chosen by the US Government and Fortune 500 firms for contracts over $10 million for Industrial furnaces and Nuclear-related vacuum furnaces. Centorr Vacuum Industries has introduced many furnace solutions over the years for applications including:

-

- Sintering

- Heat Treating

- Arc Melting

- Chemical Vapor Deposition and Infiltration

- Crystal Growth

- Fiber Optic Drawing furnaces

- 3D/Additive Manufacturing

- MIM and Continuous Belt and Pusher Furnacing.

LARGEST USER BASE OF ANY CUSTOM HIGH TEMPERATURE FURNACE MANUFACTURER.

We have over 6500 vacuum furnace units in the field. This is the largest user base of any custom high temperature furnace manufacturer. Our vacuum furnaces serve many industries including aerospace/aviation, advanced ceramics, automotive medical, electronics, military and manufacturing/industrial. Centorr Vacuum Industries has an established reputation for supplying advanced design high-temperature vacuum and controlled environment processing equipment which is expertly crafted and field-proven for dependable operation. In our last review we found over 70% of the units built since 1954 are still in service and operational, which is a testament to their design and durability.

Centorr Vacuum Industries furnaces achieve up to 95% uptime (including scheduled maintenance). This means you can count on them for consistent production with confidence.

EXACT FURNACE BUILD SPECIFICATIONS

When your furnace must be built right the first time, and to exact specifications, CVI is your choice. We build between 40 to 50 standard and custom units each year and have the corporate mind-set and infrastructure to design a furnace from the ground floor up. With over 65 different furnace configurations – we can draw from one technology for use in other processes. Most companies shy away from all-new designs requiring substantial engineering and design resources, but we do not. We specialize in and deliver prototype units that work and we offer complete support from design through furnace shipment and installation including turnkey installation if desired.

IN-HOUSE ENGINEERING - Superior quality and shorter deliveries

We have the largest engineering group in our market niche for custom vacuum furnaces, and our in-house Electrical Engineering department writes and codes all our own custom software programming ensuring tight integration with the furnace operation. Compare this with competitors who subcontract out this work to third party firms not familiar with the furnace industry, and the result is a canned package that is not as user friendly, contains non-required features which only confuse and make operating the system more difficult.

CUSTOMIZATION OF VACUUM FURNACES FOR YOUR SPECIFIC APPLICATION

Customization is probably the best advantage offered to our customer base. CVI is happy to build completely custom units. After a thorough interview of the customer's needs and process, we will build a unit that is designed specifically for the customer. Options such as:

-

- Tray Spacing

- Gas Flow Systems

- Power Supply Sizing for Specific Ramps Rates

- Mass Flow Controllers

- Emergency or Backup Water System Requirements

- Full Complement of Customized Safety Mechanisms and Interlocks

CVI only utilizes high quality vendor equipment including Allen Bradley, Honeywell, Eurotherm, Yokogawa, Varian, Leybold, BOC Edwards, and Kinney. No more settling for a furnace size that does not optimize your productivity, or results in excessive energy costs.

VACUUM FURNACE FIELD SERVICE

We have a fully staffed field service group that travels worldwide to ensure we have high quality, quick and responsive support for our customer base. This means short waits for routine field service and quick response in the case of shut-down conditions.

Compare this to companies with only a few field service engineers that take 1-2 months to schedule a visit.

CAPITAL EQUIPMENT BUSINESS STRENGTHS

CVI has the financial health and size to take on large jobs (ie – projects over $ 20 mill USD), without affecting its cash flow or manpower loading.

CVI is one of the last firms in the custom vacuum furnace market that still makes our own hot zones. We consider the hot zone the "heart" of the furnace and we have always designed and built these components in-house. Our staff of metal and graphite craftsmen have a combined experience of over 150 years of building vacuum furnace hot zones, and our large annual sales means attractive and competitive pricing from the major refractory metals suppliers and carbon/graphite machining houses.

DIVERSITY OF VACUUM FURNACE EXPERIENCE

On a Worldwide basis, users of Centorr Vacuum Industries' furnace equipment include leading government and private research organizations, universities, and manufacturing firms engaged in processing existing materials for improved properties or developing entirely new types of materials. Being on the ground floor of these new upcoming technologies gives us an advantage when scaling up the process for full scale productivity.

Over 60 years of experience in Ceramics and Metals processing means there are very few processes we haven't seen or helped develop advance heat treatment and sintering processes for.

Having designed and built capital vacuum furnace equipment for over six decades means that we have extensive knowledge of what does and doesn’t work. This saves you time and costly mistakes when specifying equipment for new or unique processes.

Tap into our knowledge base, whether it’s about integrated debinding methods, reactions between product and furnace components, or gas flow rates required for process reactions.

Contact Us

800.962.8631

603.595.7233