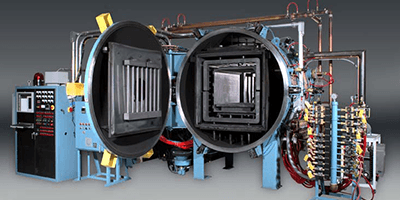

3710 Series Sintervac™ Sintering Furnaces

Sintervac™ Furnaces

For Hard Metals and Ceramics

Request Quote

3710 Sintervac™ Sintering Furnace

The Sintervac® product line services a variety of robust manufacturing requirements with delicate process control needs. Tungsten and Cemented carbides, performance and structural ceramics, cermets and high alloy steels present a few. There are over 600 Sintervacs® in field service throughout the world today. CVI is the world leader for carbide and structural ceramic applications.

Sintering Furnace Features

Key Features

- Cold Wall Vacuum Furance design with integrated cooling jackets on the vessels and doors.

- Stainless steel interior for internal contact points

- Rigid copper busswork for improved maintenance and the best electrical efficiency

- Durable Heater designs with hot zones available in both graphite and metal hot zone configurations

Specifications

| STD MODEL* | USABLE CU. FT. | EFFECT HOT ZONE WxHD (in/mm) |

|---|---|---|

| 100 | 2 (57) | 12 x 12 x 24 (305 x 305 x 610) |

| 300 | 4.5 (127) | 12 x 18 x 36 (305 x 457 x 914) |

| 500 | 9 (127) | 24 x 18 x 36 (610 x 457 x 914) |

| 600 | 12 (255) | 24 x 18 x 48 (610 x 457 x 1220) |

| 800 | 16 (453) | 24 x 24 x 48 (610 x 610 x 1220) |

BINDERS PROCESSED

- Multi-component binder systems

- Natural and synthetic waxes

- Stearic Acid and Butvar

- Polypropylene and polyethylene

- Polyvinyl Alcohol and Polyethylene Glycol

ALLOYS PROCESSED

- 316-L

- Tool Steels

- Tungsten Carbide

- High Speed Steels

- Ni, and Superalloys

Applications

CVI has specialized in process development for a variety of delube/dewax processes for carbides and ceramics. CVI process development encompasses a large effort for wax/polymer removal typical of injection molded hard metals and ceramics.

Tight pressure and gas flow control in tandem with effective event based programming and sound retort design allows the entire load to view the same series of conditions as a function of time. This results in consistent downstream microstructures and repeatable carbon control.

Depending upon the process reqirements, a variety of wax and polymer condensation strategies have been utilized including vacuum delube condensation, Sweepgas℡ condensation and CVI's proprietary BRS™ technology.

Contact Us

800.962.8631

603.595.7233