2100/2110 SERIES RESISTANCE & INDUCTION MODELS

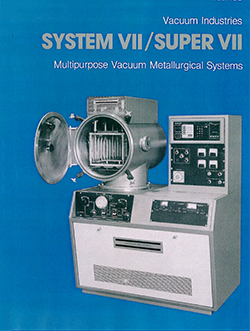

System VII/Super VII

Multipurpose Vacuum Metallurgical Systems

2100/2110 SERIES Resistance and Induction Models

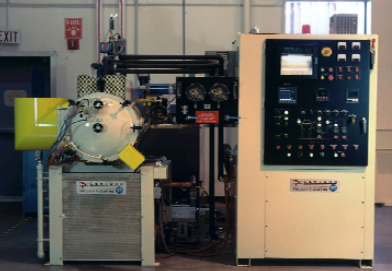

System VII and Super VII vacuum furnaces broaden the capabilities for vacuum and inert atmosphere metallurgical processes with a basic chamber concept that avoids equipment duplication and minimizes cost.

The versatile chamber accommodates accessories carefully designed to conduct all important vacuum metallurgical processes. Equipment can be chosen to meet one specific need. Should requirements change in the future, the basic system can be converted for a different process by merely substituting accessories.

Starting with the multipurpose vacuum chamber, mounted on a standard pumping system, the interchangeable accessories are easily installed to let you melt, sinter, braze, weld, outgas, anneal, heat treat or quench as desired.

Leading materials engineers and metallurgists throughout the world have selected Centorr/Vacuum Industries System VII and Super VII furnaces for the following major benefits:

- Efficiency - One multi-purpose system for all major vacuum metallurgical capabilities. Components can be added to convert from one process to another as programs, needs, and budgets change.

- Economy - Save valuable floor space while avoiding expensive equipment duplication. Meet current requirements while providing the basics for tomorrow's needs.

- Convenience - Accessory change-over is fast and easy, using ordinary hand tools. Easily removable front and rear panels allow full service access to the pumping components.

Features

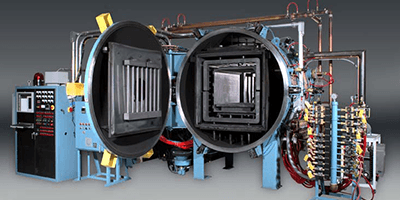

- Cold Wall Vacuum furnace design with stainless steel inner and outer jackets with baffled water cooling.

- Standard units rated at 1000°C, 1315°C, 1650°C, and 2200°C in either graphite or metal hot zones. Specials to 3000°C are available upon request.

- Available in standard sizes of 6"x6"x15" or 8"x8"x20".

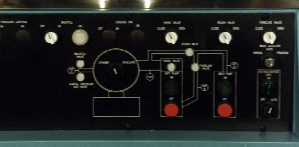

- PLC with Industrial Programmable Controller or PC system using Intellution™ FIX32 HMI software or Specview® customized by Centorr/Vacuum Industries for vacuum furnaces, with extensive data acquisition; and remote operation capabilities.

- Operation from partial pressures of 10-6 torr up to 1-3 psig positive pressures of Argon, Nitrogen, and Hydrogen.

- Our G-10503A positive pressure Hydrogen gas system with Factory Mutual (FM) approval.

- Optional binder removal systems including our patented Sweepgas™ Vacuum Binder Removal System or thermal oxidizer operating at positive pressures.

- Low and high vacuum pumping systems include mechanical pumps, diffusion, turbomolecular, or cryogenic high vacuum units with a graphic control panel.

- Single furnace chamber can be designed with interchangeable graphite and metal hot zones for flexibility while processing metals and ceramics.

- Custom systems available.

Specifications

| Horizontal Furnaces | System VII | Super VII | |||

|---|---|---|---|---|---|

| Useable Work Space | 6" x 5" x 15" lg. (150 x 150 x 380mm) | 8" x 8" x 20" lg. (200 x 200 x 500mm) | |||

| Working Volume | 0.3 ft.3 (8.6 Ltrs.) | 0.7 ft.3 (20.0 Ltrs.) | |||

| Maximum Operating Temperature | Element | Hot Zone Materials Shields/Insulation | Hearth | Hot Zone Model No. [Power Supply Rating - Vacuum] | |

| 1000°C (1830°F) | Molybdenum | Stainless Steel | Stainless Steel | 6615-1000 [10 kVA] | 8820-1000 [15 kVA] |

| 1315°C (2400°F) | Molybdenum | Molybdenum/ Stainless Steel | Molybdenum | 6615-1315 [15 kVA] | 8820-1315 [20 kVA] |

| 1650°C (3000°F) | Tungsten | Molybdenum | Molybdenum | 6615-1650 [30 kVA] | 8820-1650 [45 kVA] |

| 2200°C (4000°F) | Graphite | Graphite | 6615-22100 [30 kVA] | 8820-2100 [45 kVA] | |

| Vertical Furnaces | Heating Elements Dimensions | 4" dia. x 7" high (100 x 180mm) | 4" dia. x 7" high (100 x 180mm) | ||

| 2200°C (4000°F) | Tantalum | Tantalum | Tantalum | 47-2200 [20 kVA] | 47-2200 [20 kVA] |

| 3000°C (5432°F) | Tungsten mesh | Tungsten | Tungsten | 47-3000 [45 kVA] | 47-3000 [45 kVA] |

Optional Features

- Manual rotameter or Mass Flow Controllers for precise, repeatable gas flow.

- Integrated cooling fans with integral heat exchangers.

- CE / VDE / TüV / CSA approvals and other non-U.S. standards for compliance.

- Rigid or Flexible water cooled busswork for improved maintenance and best electrical efficiency.

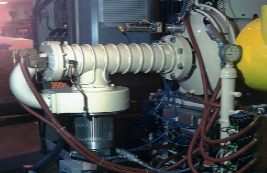

- Induction Melting Furnace for casting advanced alloys and clean metals.

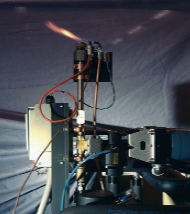

- Arc Melting Furnace to melt samples for alloy developement or phase diagram work. Includes interchangeable hearths for button, bar, or skull melting.

- Inert Gas welding systems for joining reactive refractory metals and other alloys.

- Gas Quenching options when rapid load cooling is required.

- Liquid Quench accessories available for laboratory scale oil or water quenching.

- Optional diffusion pumping system with roughing pump and water-cooled baffle, refrigerated baffle, or liquid Nitrogen cold trap.

- Optional binder removal packages including heat-traced/Insulated debind manifolding with combination diffusion pump / Dry Mechanical Pump or OTO (Once-through-oiling) pumps for a variety of binder systems.

Contact Us

800.962.8631

603.595.7233